Family Overview

Carmex has been producing tools for the Oil and Gas industries for many years. As such, we’re well aware of the industry’s unique requirements – as well as the challenges faced.

This section provides an overview of our most popular solutions.

New

New

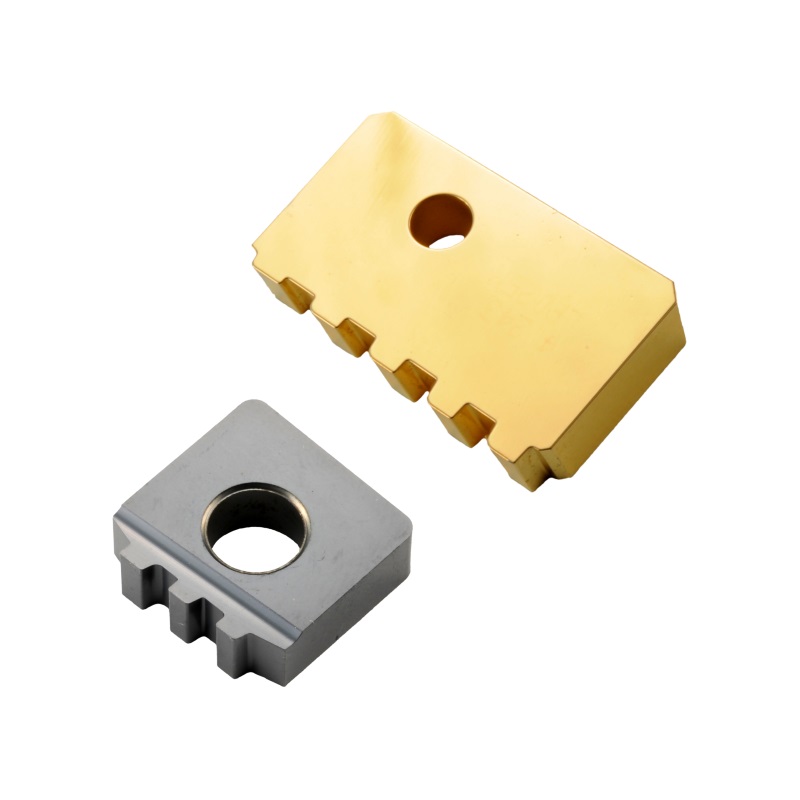

CHASERS

A product line of threading chasers. These chasers provide a high-performance solution for cutting thread profiles that are commonly used in the Oil & Gas industries.

Note:

- Currently, Carmex doesn’t have a line of tool holders designed to work with these chasers. Use them with compatible holders by other manufacturers.

Features:

- Profiles supported: API Round / API Buttress Casing / OTTM Buttress Casing

- Variants for internal and external jobs available

- 3-5 cutting teeth

Carbide Grade(s):

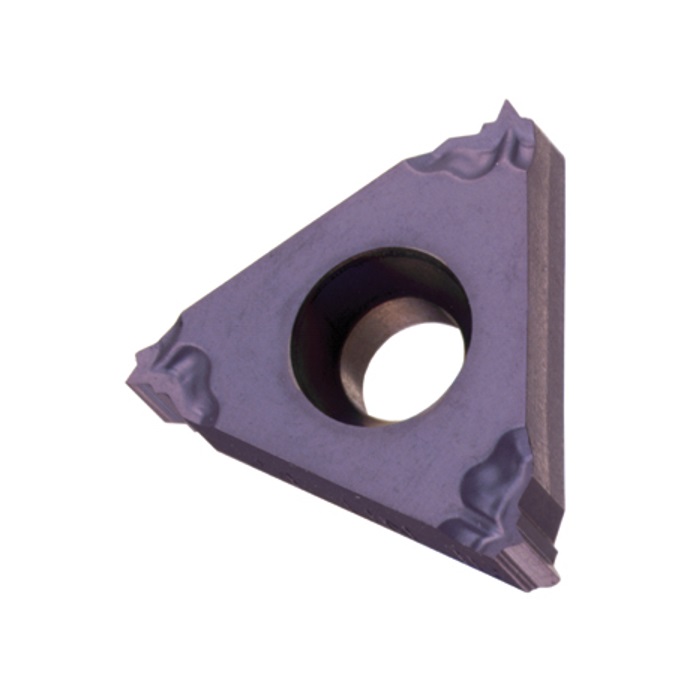

THREADING INSERTS

Our extensive range of thread turning inserts contains solutions for many thread profiles that are used in the Oil & Gas industry.

Supported profiles (relevant for Oil & Gas):

- Acme

- API

- API Buttress Casing

- API Round

- Extreme Line Casing

- Hughes H90

- NPT

- NPTF

- PAC (Pacific Asia Connection)

- Stub Acme

- VAM

Supported API thread forms:

- V-0.038R

- V-0.040

- V-0.050

- V-0.055 > Macaroni Tubing (MT)

- V-0.055 > American Macaroni Tubing (AMT)

- V-0.055 > American Mining Macaroni Tubing (AMMT)

Carbide Grade(s):

THREADING INSERTS (TYPE B)

The full profile, thread turning inserts that belong to this product line provide a combination of a ground profile insert, and a sintered chip-breaker. Unlike most other manufacturers’ inserts, this combination ensures consistent high quality thread, precise shape, and dimensions – while ensuring the chip flow.

Supported profiles (relevant for Oil & Gas):

- NPT

- NPTF

Carbide Grade(s):

THREADING INSERTS (VERTICAL)

Full profile, thread turning inserts for vertical style cutting.

Note:

- We also have a separate product line of vertical inserts for API-related thread profiles. It should be noted that standard vertical holders cannot be used with those inserts.

Supported profiles (relevant for Oil & Gas):

- Acme

- NPT

Carbide Grade(s):

THREADING INSERTS (MULTITOOTH)

A new generation of thread turning inserts offers multiple cutting teeth per side, for maximum performance.

Supported profiles (relevant for Oil & Gas):

- API Round

- NPT

- NPTF

Carbide Grade(s):

EXTERNAL HOLDERS

Tool holders for turning inserts. The holders that belong to the current line of products support only external threads/grooves.

Features:

- Left-hand and right-hand variants available

- Optional “U-Type” tool holders are compatible with “U-Type” thread turning inserts

- Most tool holders are made with a 1.5° helix angle. For other angles, please consult the helix angle chart.

EXTERNAL HOLDERS WITH TOP CLAMP

External tool holders for turning inserts. These holders have an additional clamp for extra insert fastening security.

Features:

- Left-hand and right-hand variants available

- Most tool holders are made with a 1.5° helix angle. For other angles, please consult the helix angle chart.

Notes:

- Two clamping methods can be used: Screw / Top Clamp

- For DER 2525 M22 and DER 1000 M22, use the K21 torx key for C22 clamp

EXTERNAL VERTICAL HOLDERS

Tool holders for external, vertical style thread turning jobs.

Notes:

- These tool holders can only be used with vertical thread turning inserts – either partial profile, or full profile.

SLIM THROAT HOLDERS

Tool holders for external, vertical style thread turning jobs. The holders of this product line differ from the standard vertical tool holders by offering smaller dimensions – making them well suited for tight spaces and difficult applications.

Notes:

- These tool holders can only be used with vertical thread turning inserts – either partial profile, or full profile.

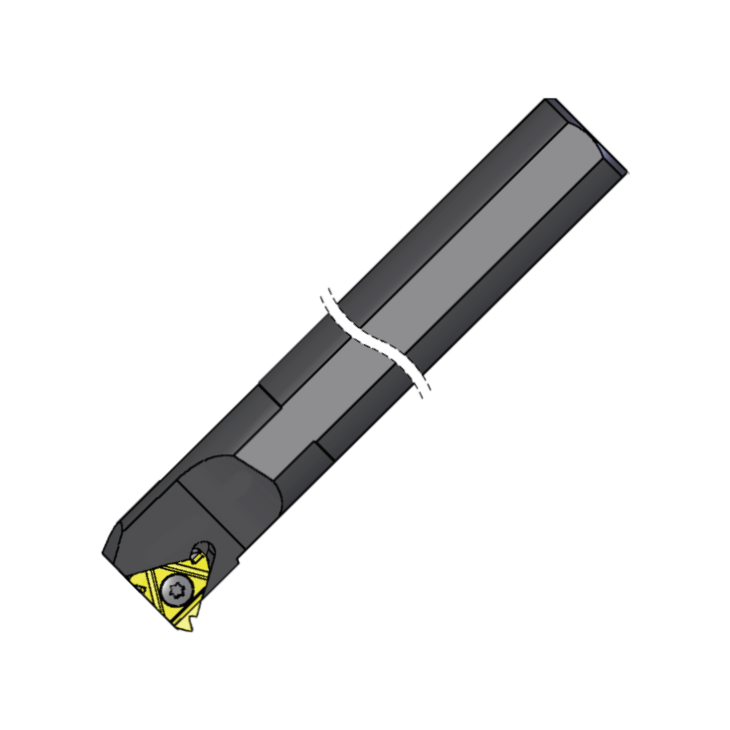

INTERNAL HOLDERS

Tool holders for turning inserts. The holders that belong to the current line of products support only internal threads/grooves.

Features:

- Left-hand and right-hand variants available

- Optional “U-Type” holders are compatible with “U-Type” thread turning inserts

- Most tool holders are made with a 1.5° helix angle. For other angles, please consult the helix angle chart.

INTERNAL HOLDERS WITH COOLANT BORE

Tool holders for cutting internal threads/grooves. These holders improve on the basic internal tool holders by adding an integrated coolant bore. The coolant fluid helps to evacuate the chips, which helps to maximize tool performance, as well as extend the life of the insert.

Features:

- Left-hand and right-hand variants available

- Most tool holders are made with a 1.5° helix angle. For other angles, please consult the helix angle chart.

INTERNAL HOLDERS WITH TOP CLAMP

Internal tool holders for turning inserts. These holders have an additional clamp for extra insert fastening security.

Features:

- Left-hand and right-hand variants available

- Most tool holders are made with a 1.5° helix angle. For other angles, please consult the helix angle chart.

Notes:

- Two clamping methods can be used: Screw / Top Clamp

- For DIR 0025 R22 and DIR 1000 R22, use the K21 torx key for C22 clamp

HOLDERS WITH 3.5° HELIX ANGLE

Tool holders for internal turning jobs. Unlike the standard holders that use a 1.5° helix angle, the tool holders that belong to the current product line use 3.5°.

Typically, one would consider using such a tool holder in case of a large-pitch thread with a relatively small diameter.

CARBIDE SHANK BARS

These carbide shank bars can be used to cut internal threads/grooves. They are especially well-suited for deep small bores with a long overhang, or for use in other situations, where chatter and deflection are expected. These bars have an integrated coolant bore, which helps with chip evacuation. This helps to maximize tool performance, as well as extend the life of the insert.

Features:

- Left-hand and right-hand variants available

INTERNAL VERTICAL HOLDERS

Tool holders for internal, vertical style thread turning jobs.

Features:

- Left-hand and right-hand variants available

Notes:

- These tool holders can only be used with vertical thread turning inserts – either partial profile, or full profile.