Family Overview

Our solid carbide grooving tools are specially designed for grooving deep parts. The tools support internal coolant (either through the flutes, or through an internal bore), which is especially effective when deep holes are involved.

Features:

- Spiral flutes enable smooth cutting action

- Longer tool life due to special multi-layer coating (MT8)

- Shorter machining time due to multiple (3-6) flutes

Our range of solid carbide grooving tools consists of the following lines:

GROOVE MILLING TOOLS

Our basic line of solid carbide groove mills. Supports grooving diameters as small as 4 mm.

Features:

- 3-5 spiral flutes

- Internal cooling through the flutes

- Same tool can be used for internal and external grooving

Carbide Grade(s):

FULL RADIUS GROOVE MILLING TOOLS

These grooving mills are capable of performing “Full Radius” groove jobs. They can support grooving diameters as small as 4 mm.

Features:

- 3-5 spiral flutes

- Internal cooling through the flutes

- Same tool can be used for internal and external grooving

Carbide Grade(s):

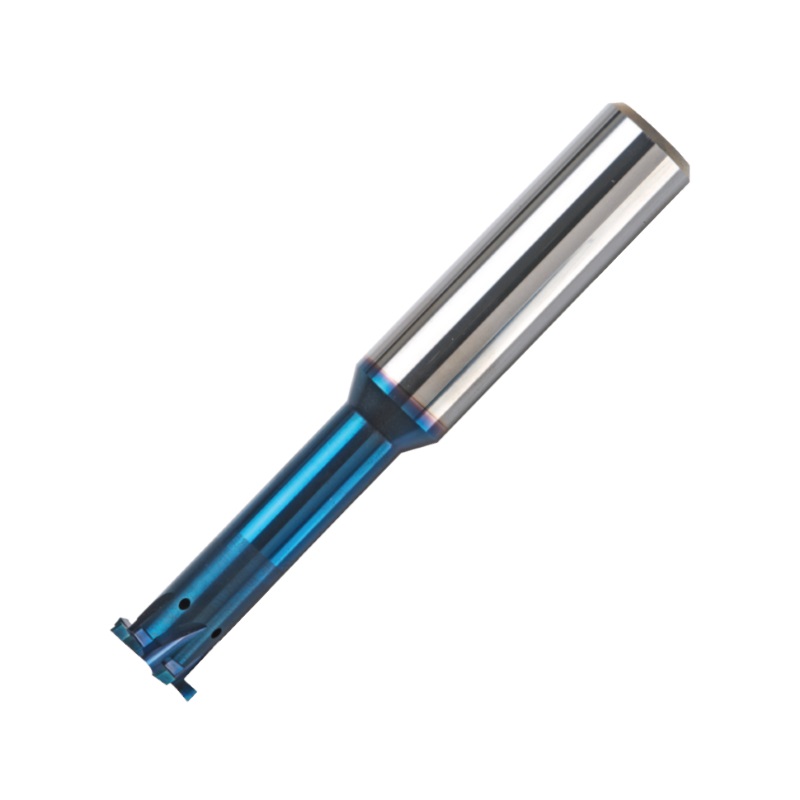

DEEP GROOVE MILLING TOOLS

A line of solid carbide grooving tools especially designed for machining deep holes (as deep as 130 mm). These tools require a minimum groove diameter of 19.5 mm.

Features:

- 6 spiral flutes

- Internal cooling through a bore

Carbide Grade(s):