Family Overview

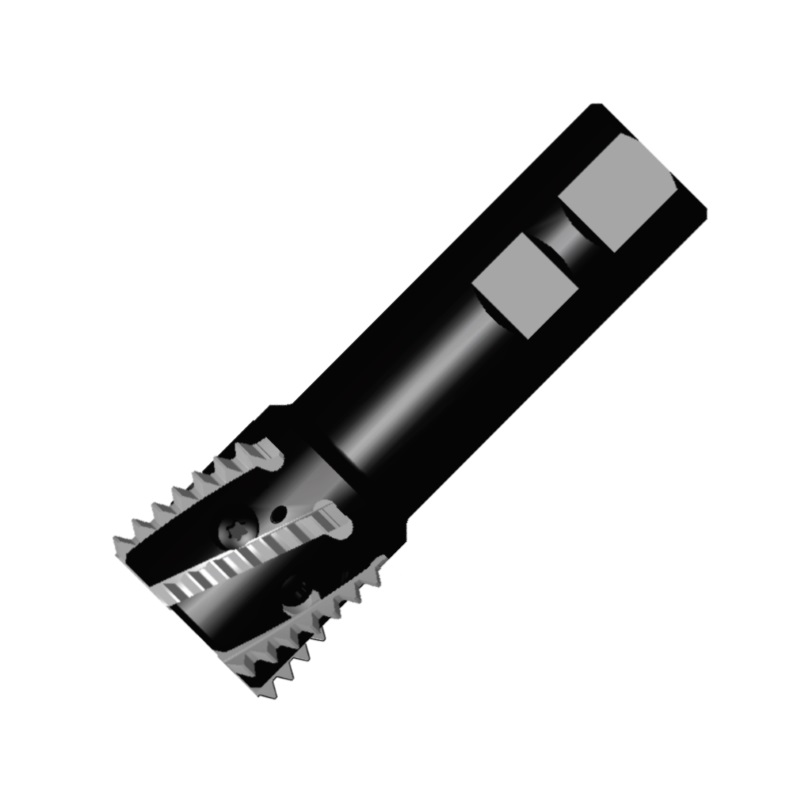

The Spiral Mill-Thread family of indexable tools is a family of tools that use a spiral-based design. Each spiral-fluted tool holder contains anywhere between 1 and 9 inserts, in a comparatively small cutting diameter. This makes the tools well-suited for a wide range of applications: From machining minuscule components in small machining centers, to heavy-duty applications in high-power milling machines.

Features:

- Spiral tools reduce vibration and chatter

- High-quality finish is achieved in all applications

- Tools allow for a smooth cutting operation at at high feed rates, reducing machining times

- Unique clamping method enables optimal indexability

The following product lines can used for finishing:

FINISHING INSERTS

The inserts of this product line were developed in order to enable the machining of various finishing and semi-finishing applications.

Carbide Grade(s):

TOOL HOLDERS

A product line of basic holders for the Spiral Mill-Thread family of tools. All holders in this line have internal coolant bore, allowing an efficient delivery of coolant fluid to the cutting edges.

Features:

- Multi (1-5) inserts per holder

Note:

- SRH17-2 / SRH17J-2 / SR0670H17-2 / SR0670H17J-2: When using inserts for the conical threads (NPT / NPTF / BSPT), the cutting diameter (D) becomes 18 mm / 0.71 inch.

TOOL HOLDERS (WITHOUT NECKS)

Unlike the tools that belong to the line of basic Spiral Mill-Thread holders, the holders in this line use slightly different geometries, as they don’t have a “neck”. These holders are equipped with an internal coolant bore, enabling efficient removal of chips from the hole.

Features:

- Multi (4-6) inserts per holder

SHELL MILL HOLDERS

A product line of shell mill holders with an internal coolant bore.

Features:

- Multi (5-9) inserts per holder