Family Overview

Vertical milling indexable inserts and tool holders that support a variety of threads, grooves, chamfers, and more.

Features:

- Ground profile inserts for high precision and excellent performance

- Working at high machining parameters, with high surface quality

- Solid and accurate clamping method enables full repeatability

- Same insert can be used for both right-hand and left-hand threads

The following product lines can used for chamfering:

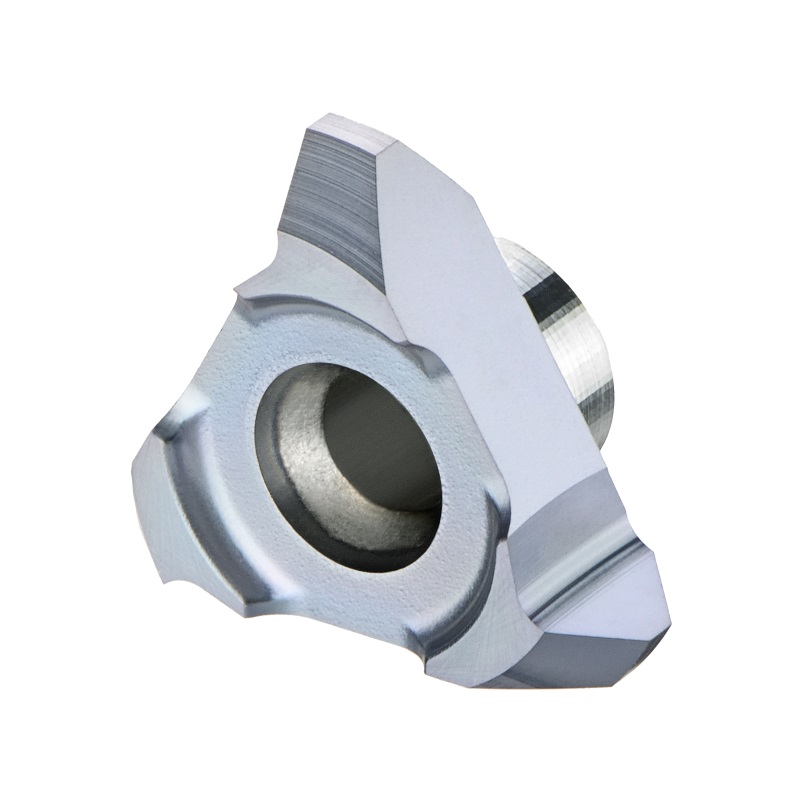

CHAMFERING AND GROOVING INSERTS (SINGLE FLUTE)

A line of inserts that support both chamfering and grooving jobs.

Carbide Grade(s):

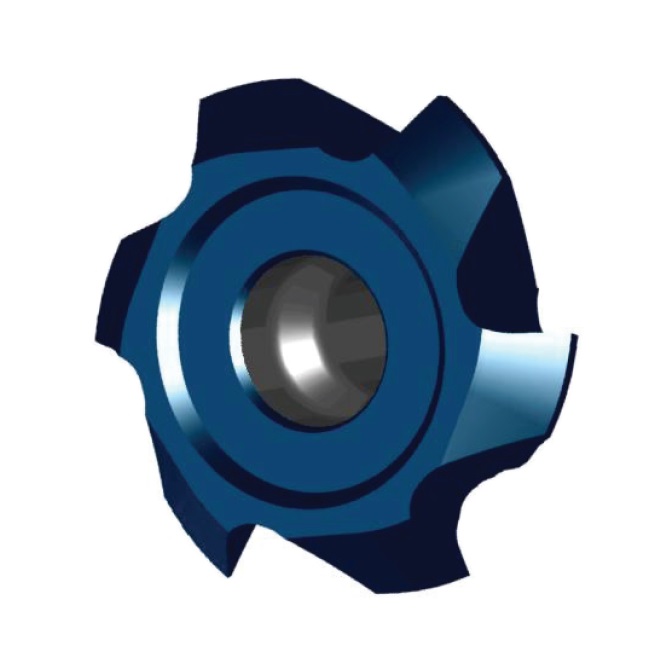

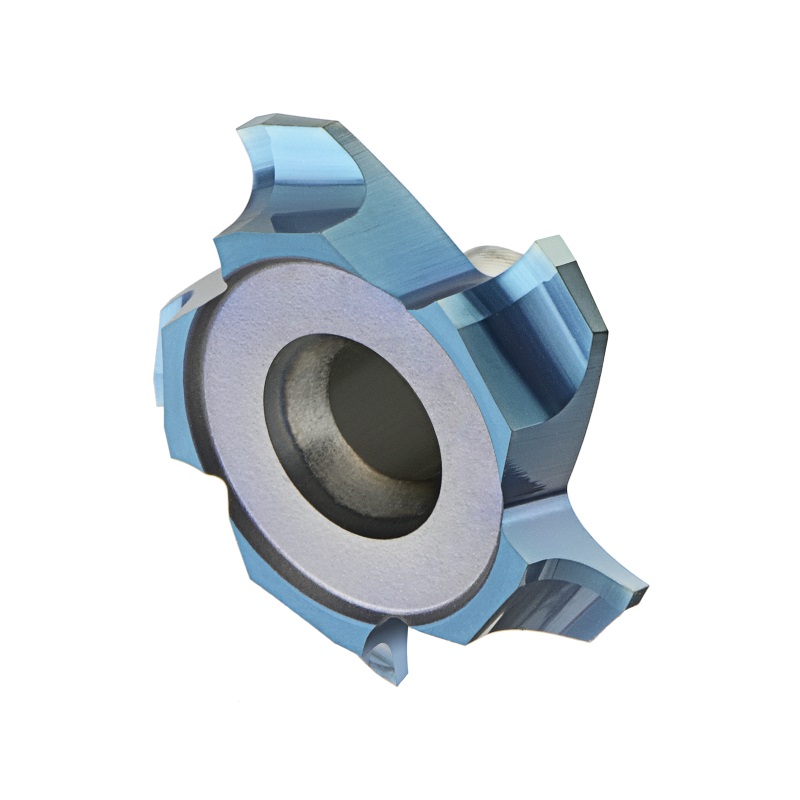

CHAMFERING, GROOVING, AND BORING INSERTS (MULTI FLUTE)

A line of inserts that can handle chamfering, grooving, and boring jobs.

Features:

- Multi (5-6) flutes

Carbide Grade(s):

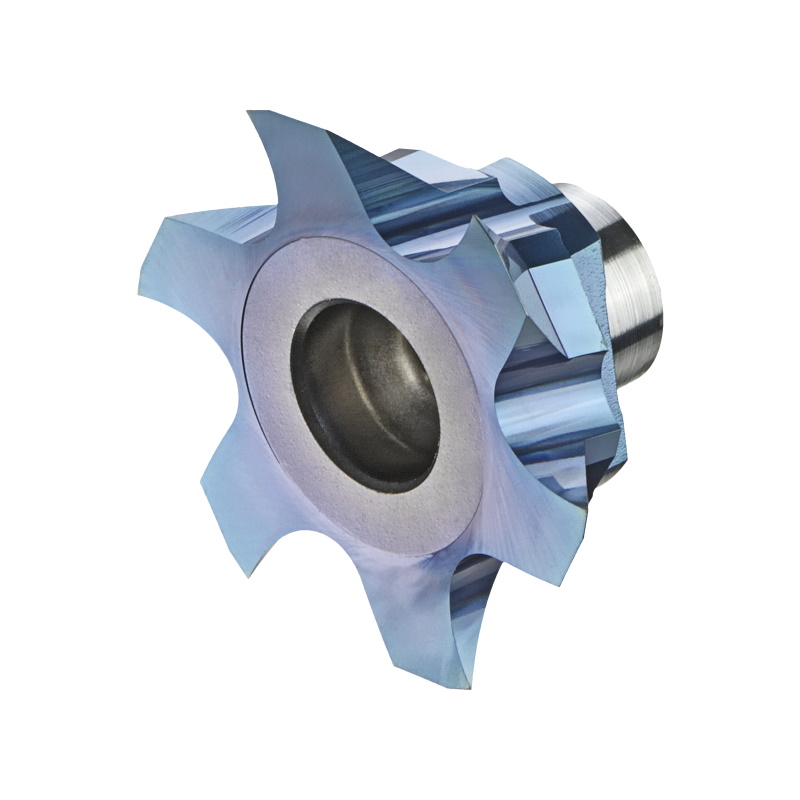

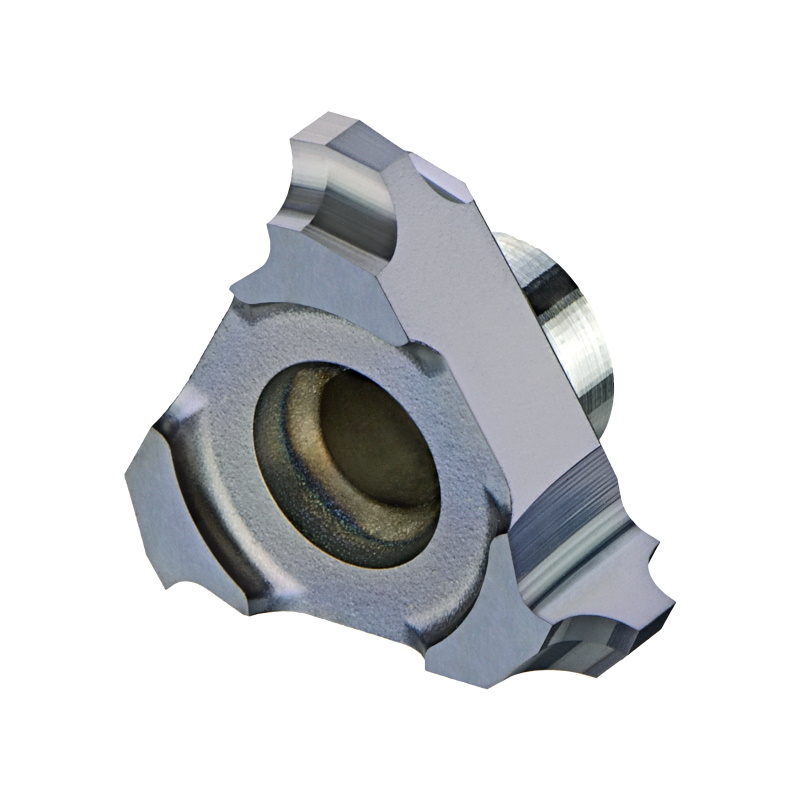

CHAMFERING, GROOVING, AND BORING INSERTS (MULTI FLUTE, DOVETAIL 45°)

A variation of the previous line, the geometry of these inserts has been redesigned to support dovetail operations.

Features:

- Multi (6) flutes

Carbide Grade(s):

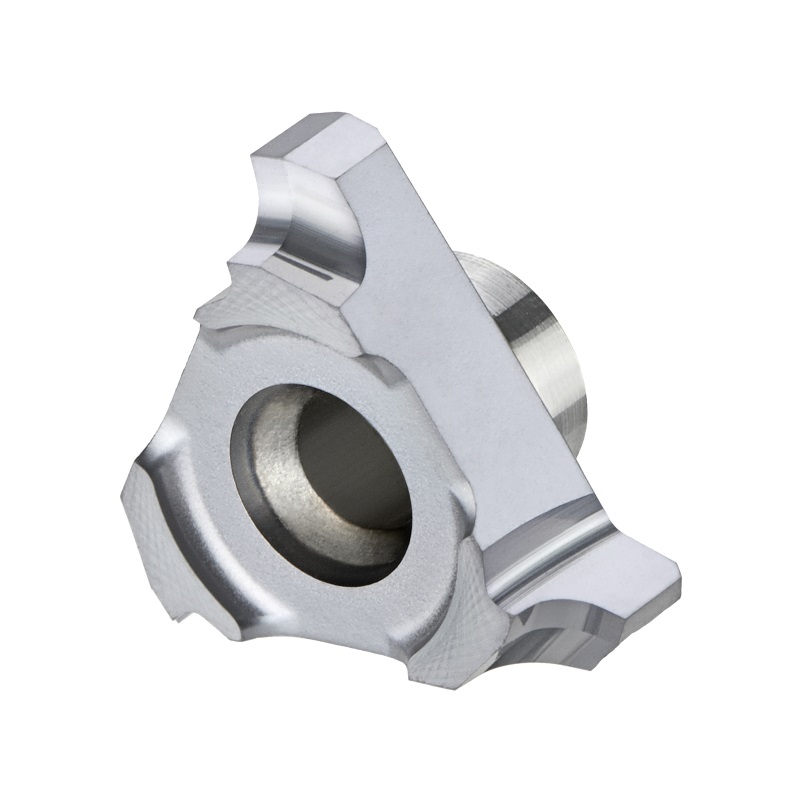

CORNER ROUNDING INSERTS (SINGLE FLUTE)

A line of inserts specially designed to perform rounding operations on external, sharp corners.

Carbide Grade(s):

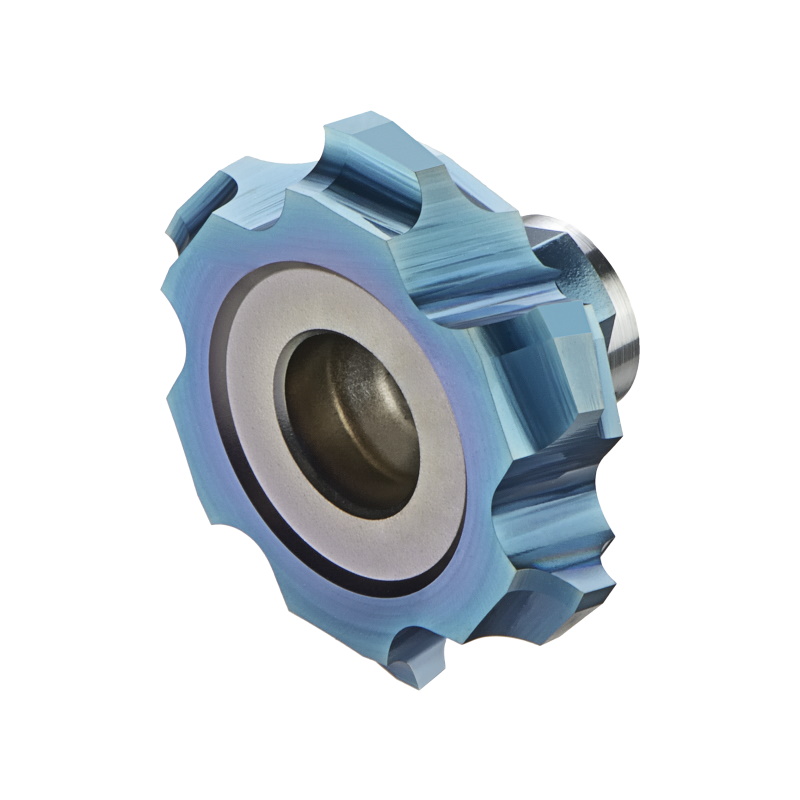

CORNER ROUNDING INSERTS (MULTI FLUTE)

A second generation of inserts specially designed to perform rounding operations on external, sharp corners. The multiple spiral flutes allow for improved performance, and a longer tool life.

Features:

- Multi (5) flutes

Carbide Grade(s):

FRONT/BACK CORNER ROUNDING INSERTS (SINGLE FLUTE)

Corner rounding inserts, compatible with both front and back operations.

Carbide Grade(s):

FRONT/BACK CORNER ROUNDING INSERTS (MULTI FLUTE)

Corner rounding inserts, compatible with both front and back operations. This version comes with multiple spiral flutes that extend the tool life expectancy, and improve performance.

Features:

- Multi (6) flutes

Carbide Grade(s):

STEEL TOOL HOLDERS

Features:

- Internal Coolant

- Weldon Shank

CARBIDE SHANK TOOL HOLDERS

Features:

- Internal Coolant

MODULAR TOOL HOLDERS (SRCM)

A modular tooling system that enables the customer to conveniently use a wide set of tools, optimized for various applications. This allows for a substantial reduction of tool inventory, and eliminates the need for custom tools.

Every modular CMT tool can be used with an extension from the Carmex Deep Reach family, or with common steel/carbide extensions by other manufacturers. The holders accept standard CMT inserts (types C25 or S35).

Features:

- Rigid tool assembly enables the cutting depth to be increased without compromising stability

- Internal Coolant