Family Overview

In many companies, Swiss-type machines are becoming a popular alternative to large lathes and machining centers. As a result, we developed a family of indexable tools designed for use with automatic lathes and Swiss-type machines. These tools enable high-volume, cost-efficient machining of external grooving, back/front turning, profiling, thread turning, parting, and general turning applications.

Features:

- Grounded cutting edges

- The inserts can be indexed directly on the machine

- Coated holders provide abrasion resistance

The following product lines can used for chamfering:

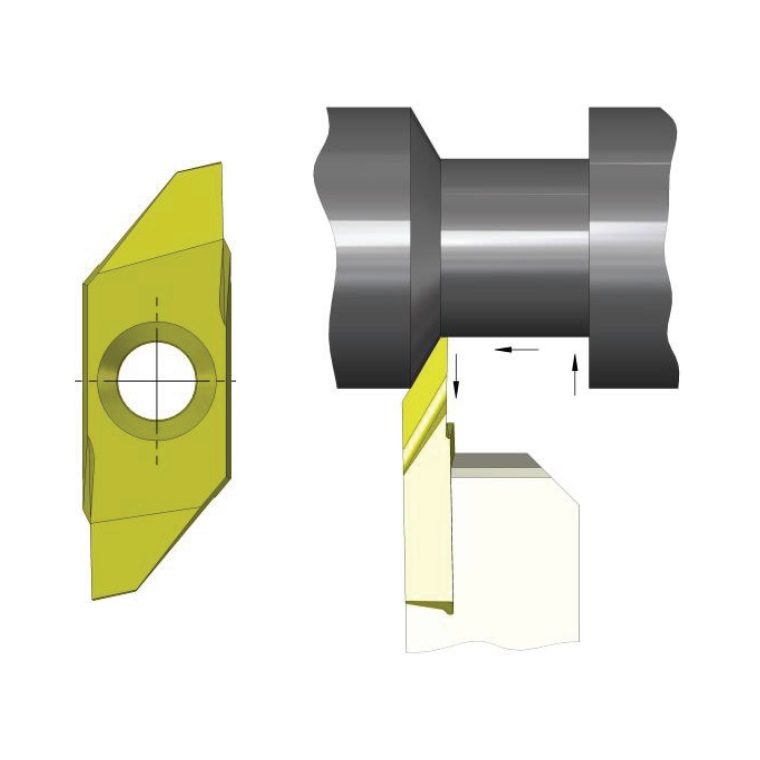

POLYGON BACK TURNING INSERTS

A product line of inserts, designed for the efficient processing of back turning applications. Additionally, they can also be used in chamfering and general turning jobs. These inserts (and all polygon inserts in general) are optimized towards the production of small parts.

Features:

- Variants for both right-hand and left-hand jobs are available

Carbide Grade(s):

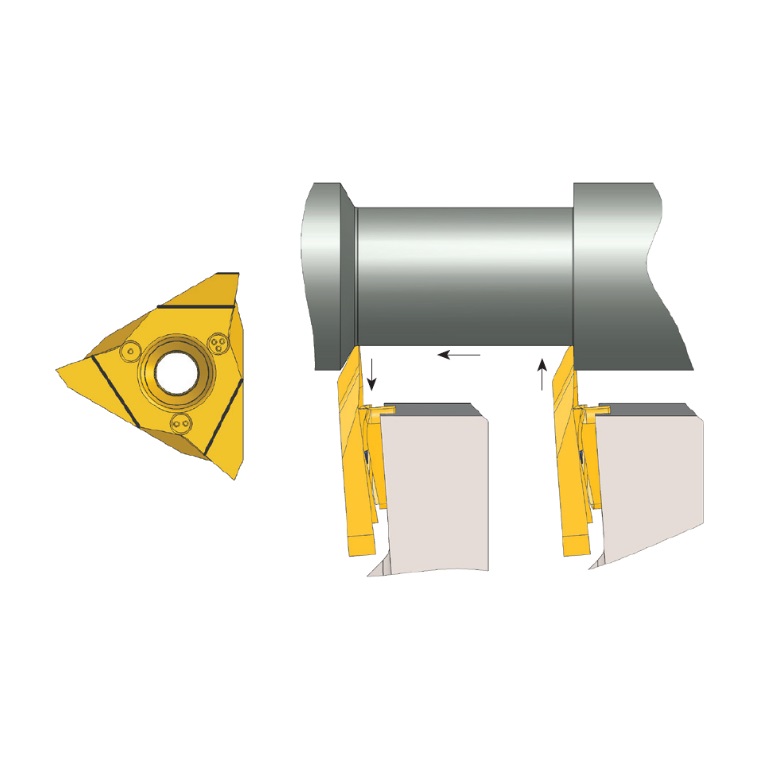

3 CUTTING EDGES BACK TURNING INSERTS

These inserts – which have 3 cutting edges – were created primarily to process back turning applications on Swiss-type machines. In addition, they can be used to machine chamfering jobs, and for general turning applications.

Features:

- Variants for both right-hand and left-hand jobs are available

Carbide Grade(s):

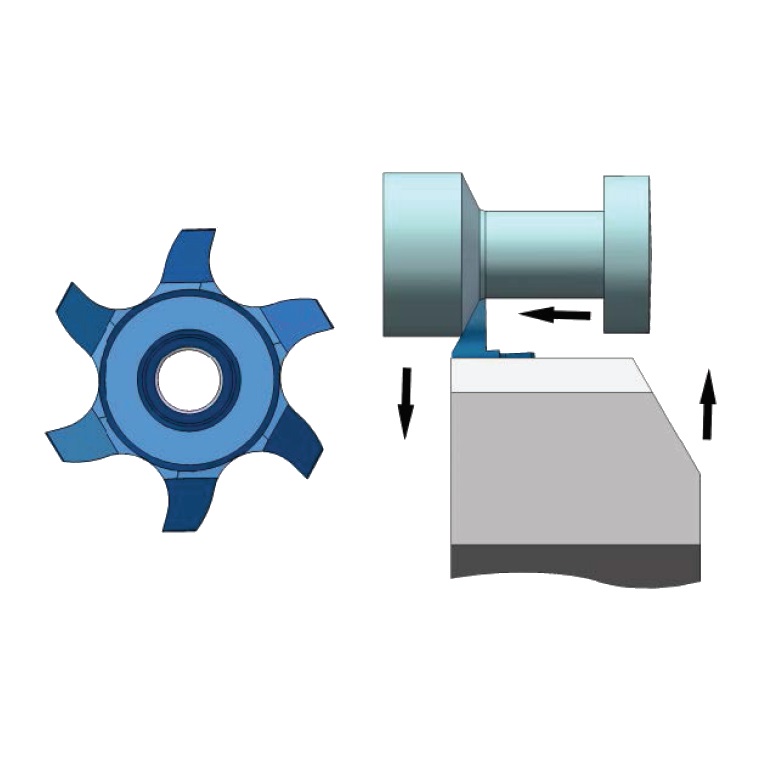

G6 (6 CUTTING EDGES) BACK TURNING INSERTS

A product line of inserts with 6 cutting edges, for use with Swiss-type machines (just like all other G6 inserts). These inserts were originally developed in order to process back turning applications. However, they can also be used for external chamfering and general turning jobs.

Features:

- Variants for both right-hand and left-hand jobs are available

Carbide Grade(s):

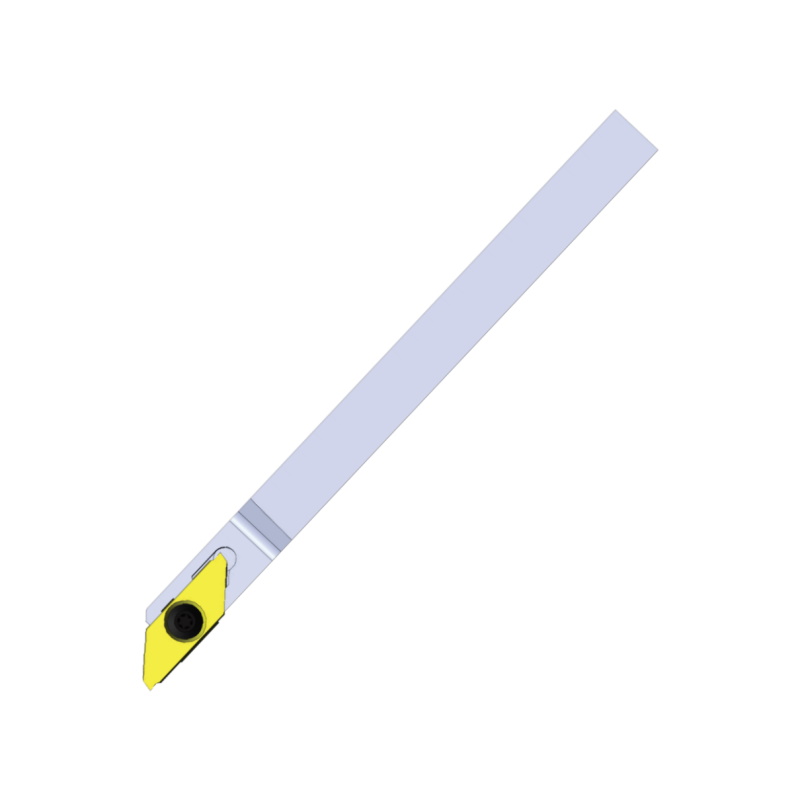

POLYGON TOOL HOLDERS (WITHOUT COOLANT)

A product line of external holders for Polygon inserts from the Swiss-Line family. These holders do not support through-coolant.

Features:

- Each Polygon insert is compatible with every holder in the line (“one size fits all”)

- Variants available for right-hand and left-hand applications

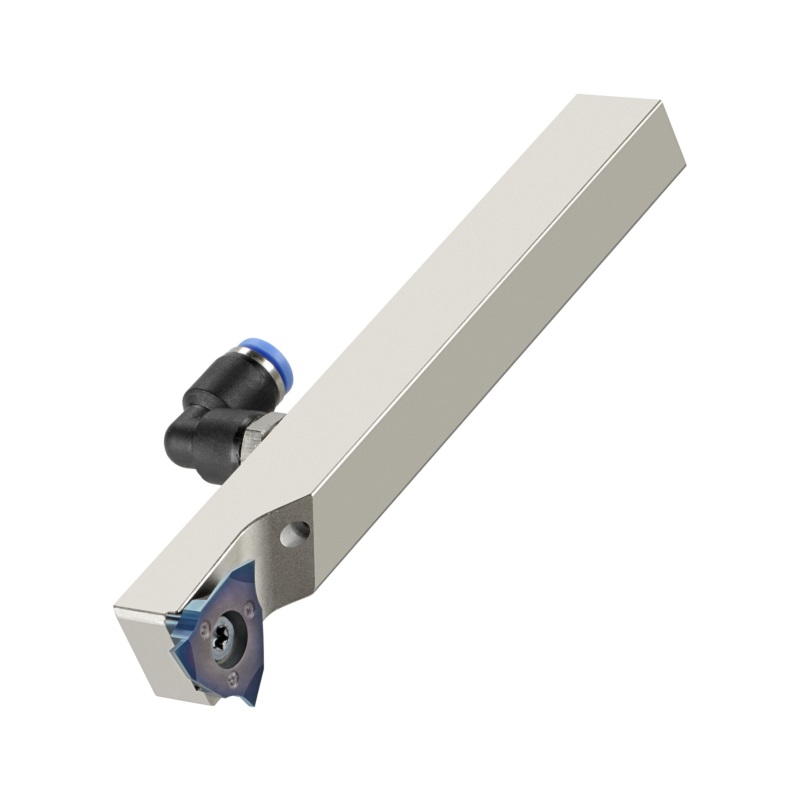

POLYGON TOOL HOLDERS (WITH COOLANT)

External holders for Polygon inserts from the Swiss-Line family. These holders provide an upgrade over the basic Polygon holders, by including support for through-coolant (via the included coolant connector).

Features:

- The coolant connector allows for fast attachment on the machine

- Each Polygon insert is compatible with every holder in the line (“one size fits all”)

- Variants available for right-hand and left-hand applications

POLYGON TOOL HOLDERS (SLIM)

A line of external holders for Polygon inserts from the Swiss-Line family, without through-coolant support. The slimmer bodies of these holders make them a great choice for small applications.

Notes:

- Unlike in the other product lines, the holders of this line only support Left-hand jobs.

3 CUTTING EDGES TOOL HOLDERS (19/20 MM)

This product line contains external tool holders designed to work with Swiss-Line inserts with 3 cutting edges (sized 19 mm and 20 mm). Similar to other Swiss-Line holders, they too have been developed for the purposes of machining external turning applications in Swiss-type machines. They include support for through-coolant(*) (via the included coolant connector), which aids in prevention of potentially damaging chip buildup.

(*) Except for GER 0816 K and GEL 0816 K

Features:

- The coolant connector allows for fast attachment on the machine

- Variants available for right-hand and left-hand applications

3 CUTTING EDGES TOOL HOLDERS (19/20 MM, SLIM)

The external tool holders in this product line work in conjunction with 3 cutting edge inserts from our Swiss-Line family (only those with sizes of 19 mm and 20 mm). They differ from the basic “3 cutting edges” holders, by offering slimmer bodies and necks – making them well suited for smaller applications (though of course they can be used with standard applications as well). Just like with all other Swiss-Line holders, the main purpose of these holders is the machining of external turning applications in Swiss-type machines. They come with an integrated coolant connector which enables through-cooling to be used.

Features:

- The coolant connector allows for fast attachment on the machine

- Variants available for right-hand and left-hand applications

G6 (6 CUTTING EDGES) TOOL HOLDERS

A product line of external holders for G6 inserts from the Swiss-Line family. Like all Swiss-Line holders, these holders are designed for machining of external turning applications in Swiss-type machines. They include support for through-coolant(*) (via the included coolant connector), helping to evacuate the chips as they are created – thus preventing a potentially damaging chip buildup.

(*) Except for G6ER/L 1212 K, TGER/L 1212 K, and G6ER/L 0500 K

Features:

- The coolant connector allows for fast attachment on the machine

- Each G6 insert is compatible with every holder in the line (“one size fits all”)

- Variants available for right-hand and left-hand applications