Family Overview

Our versatile range of solutions for production of gears, splines, and racks consists of multiple tool families. This range includes a wide assortment of insert geometries and grades, and can be used to machine different profiles (including DIN 5480, DIN 3960, and ASA B5.15-1950 standards).

Our solutions are typically based on standard Carmex tool holders, and tailor-made inserts. This allows us to achieve short delivery times – while maintaining maximum flexibility. All tools come with fully ground, highly-accurate profiles.

Every gear/ spline application has its own geometry and specifications. In order for us to be able to provide the best possible solution, we need to know the gear / spline standard, and whether a solid carbide or an indexable tool is preferred. Additionally, we need a complete drawing of the required gear / spline standard, including the following information:

- Shape of tooth

- Number of teeth

- Major, pitch, and minor diameter

- Quality requirements

- Gear / spline material

Below is a list of families / lines, from which a solution for a gear milling application can be sourced. For additional information, see the following brochure:

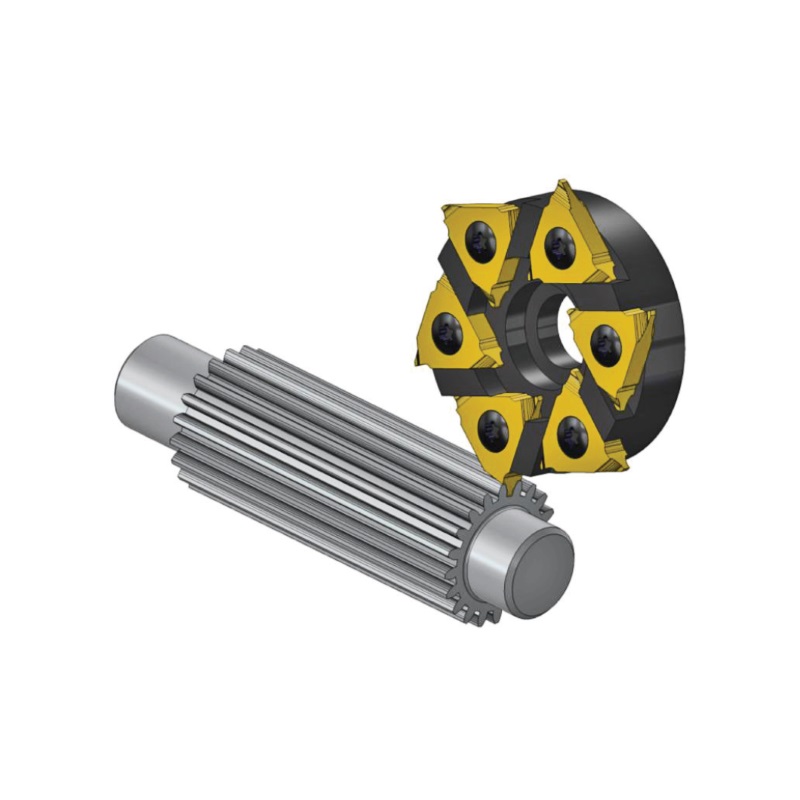

U-TYPE INSERTS

These inserts and matching holders are especially well-suited for machining relatively large profiles, and high-powered cuts.

Features:

- Shell mill or weldon shank holders

- Up to three cutting edges per insert

- High precision insert pockets and tips to ensure small run-outs

V-TYPE INSERTS

Features:

- Up to three cutting edges per insert

- High precision insert pockets and tips to ensure small run-outs

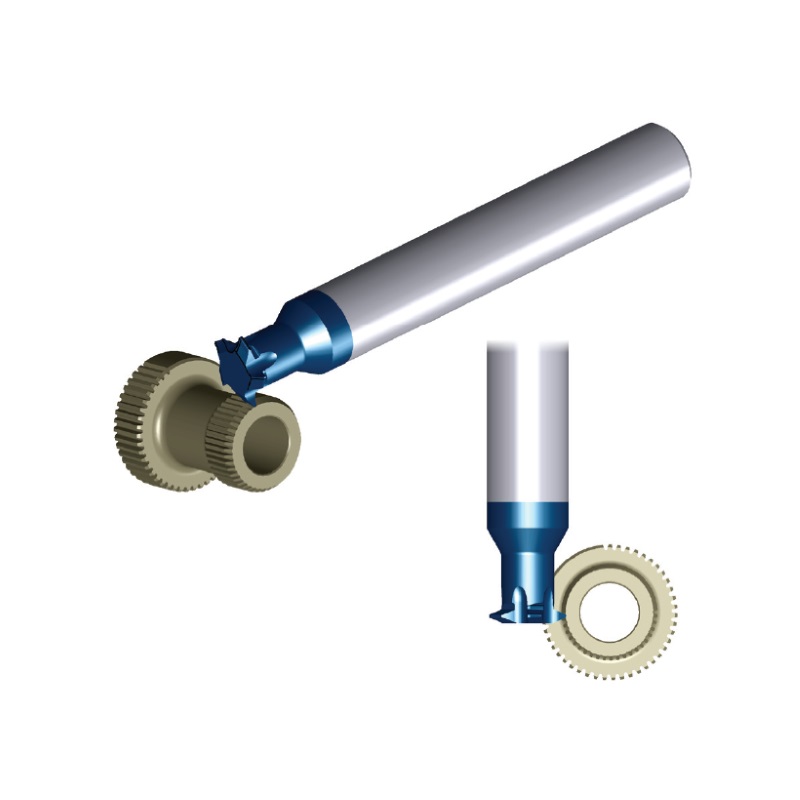

MTI - MINI MILL-THREAD

Solid carbide tools for improved rigidity and stability. These tools are especially useful when dealing with small and medium profiles.

Features:

- 3 to 6 cutting edges

- High-performance grades

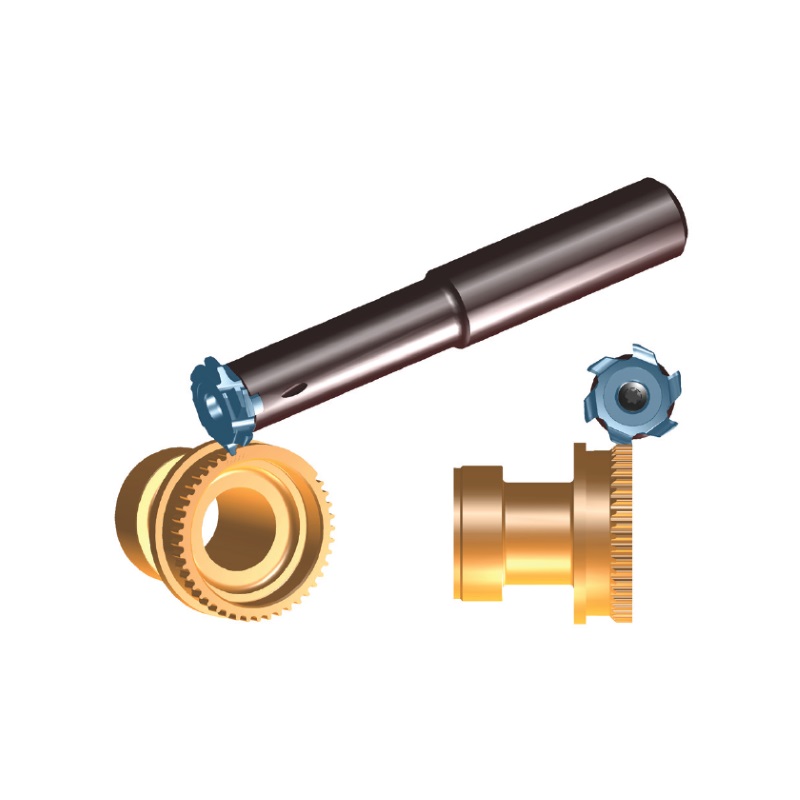

CMT VERTICAL MILLING

Vertical gear milling cutters with indexable inserts. These cutters support internal coolant, helping to avoid chip buildup during operation.

Features:

- 3 to 4 cutting edges

- To be used with standard steel or carbide shank CMT tool holders

CMT MULTI FLUTE

Vertical cutters with multiple spiral flutes for high performance, and smooth cutting action. These cutters support internal coolant, helping to avoid chip buildup during operation.

Features:

- 6 to 8 spiral flutes

- To be used with standard steel or carbide shank CMT tool holders