Family Overview

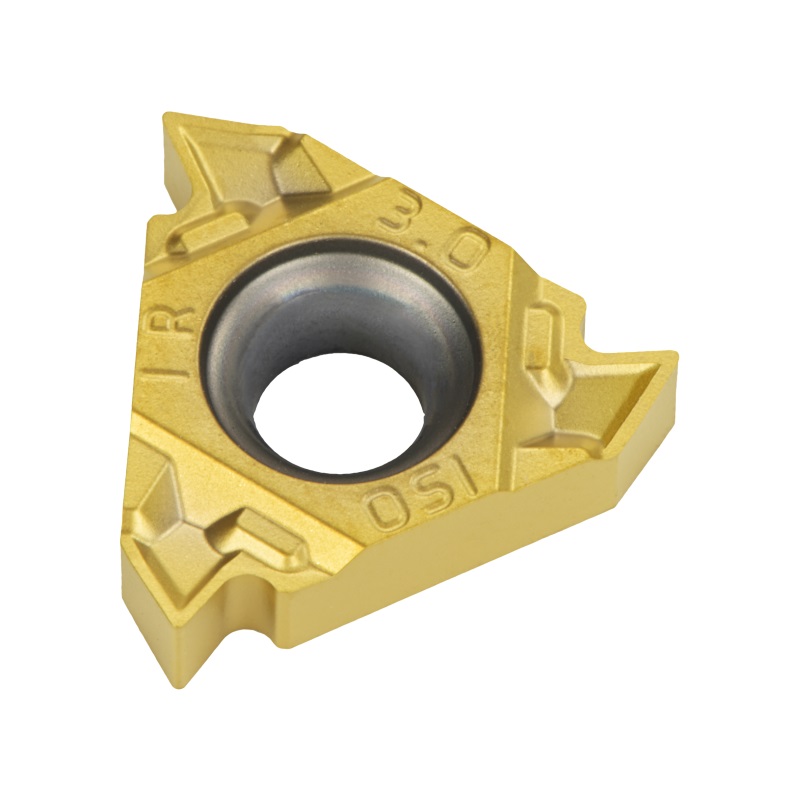

Our industry-leading range of thread turning inserts is recognized worldwide. These high-quality laydown triangular inserts can provide a solution for the majority of the thread standards available today. They can handle a wide range of applications: From the basic, to the most demanding ones.

Features:

- A large variety of grades and coatings tailored for different materials and manufacturing processes

- High-quality threads produced by the inserts

- Capable of cutting threads as small as 0.5 mm

- Inserts available for internal and external jobs, and both right-hand and left-hand threads

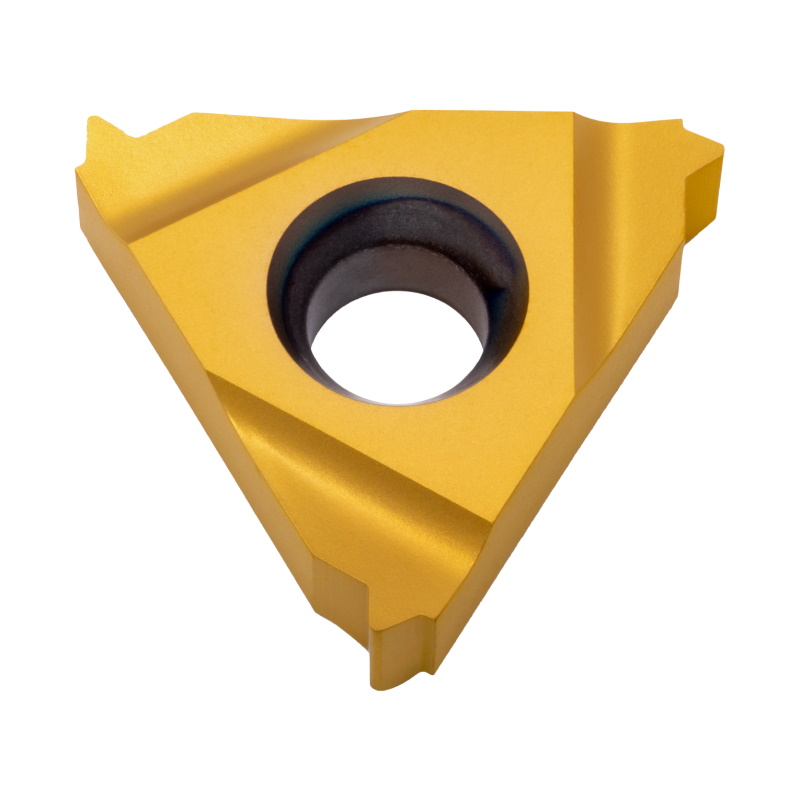

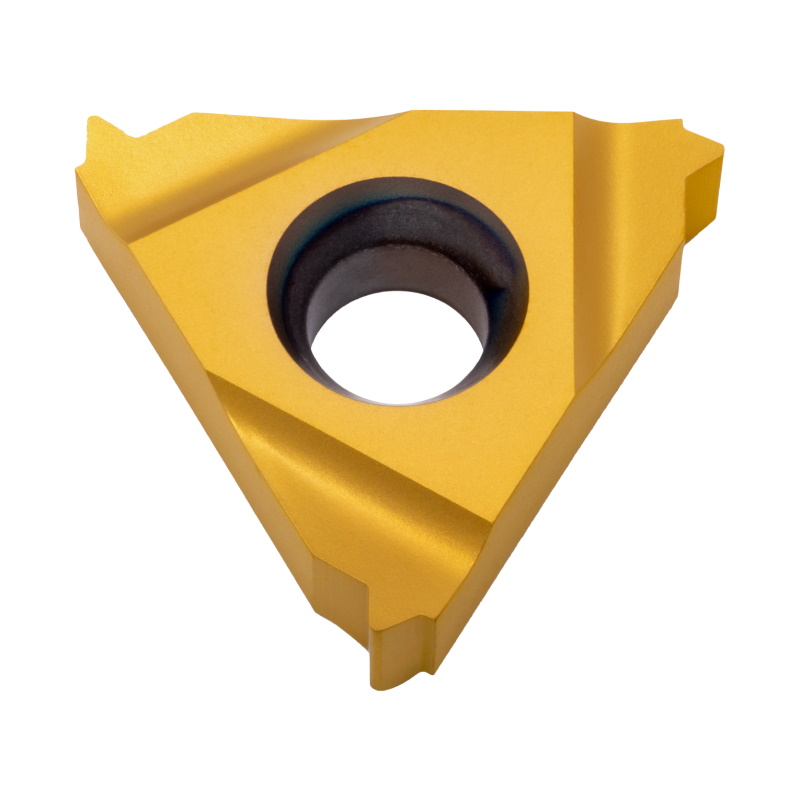

THREADING INSERTS (PARTIAL PROFILE)

Versatile, cost-effective thread turning inserts. Each insert is compatible with a range of thread pitches.

Features:

- Compatible with 60° and 55° profiles

- Solutions available for pitches up to 9.0 mm / 2.75 TPI

- Ultra Miniature and Miniature inserts for pitches as small as 0.5 mm

Carbide Grade(s):

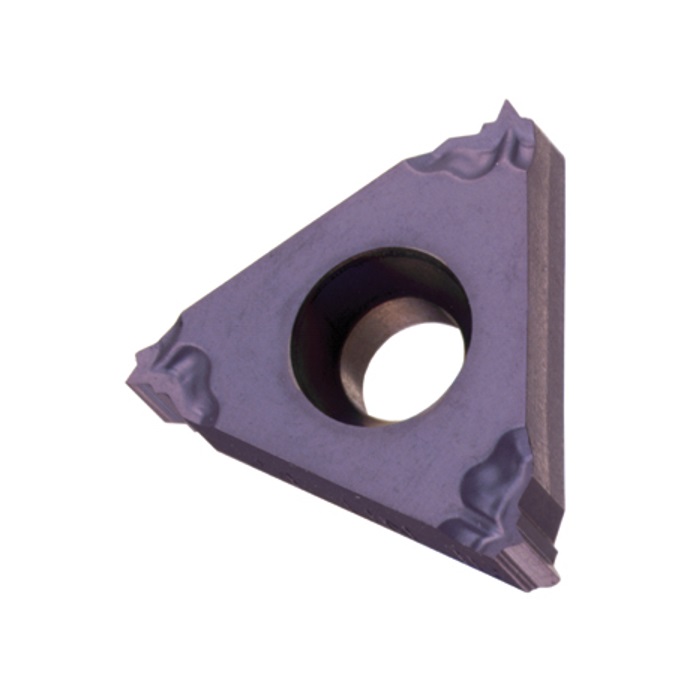

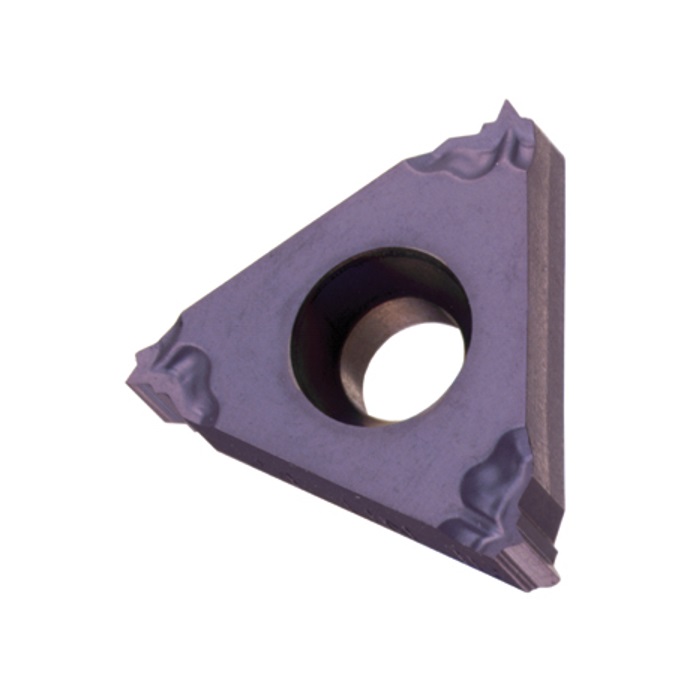

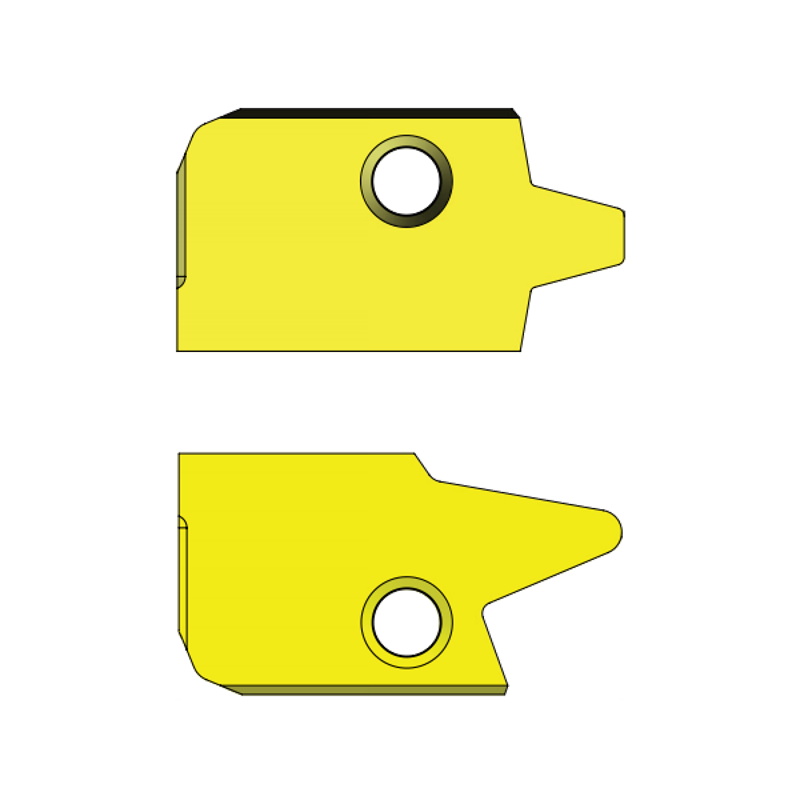

THREADING INSERTS (PARTIAL PROFILE, TYPE B)

The partial profile, thread turning inserts that belong to this product line provide a combination of a ground profile insert, and a sintered chip-breaker. Unlike most other manufacturers’ inserts, this combination ensures consistent high quality thread, precise shape, and dimensions – while ensuring the chip flow.

Features:

- Solutions available for pitches up to 3.0 mm / 8 TPI

- Two different chip-breaker styles are used, in order to suit the different requirements of Internal and External threads

Carbide Grade(s):

THREADING INSERTS (PARTIAL PROFILE, VERTICAL)

Partial profile, thread turning inserts for vertical style cutting.

Features:

- Compatible with 60° and 55° profiles

- Solutions available for pitches from 0.5 mm to 10.0 mm / 2.5 TPI

Carbide Grade(s):

THREADING INSERTS (PARTIAL PROFILE, TYPE K)

Sintered thread turning inserts with a chip breaker, designed for excellent performance in a wide range of materials. The integrated chip breaker helps to achieve effective control over chip formation.

Features:

- High edge-line security ensures dependable machining results

- Compatible with stock Carmex thread turning holders

Carbide Grade(s):

THREADING INSERTS (FULL PROFILE)

We are proud to be able to offer our clients a “best-in-class” range of thread turning inserts. Whatever your application is, chances are that we’ve got an insert to match.

Features:

- Support for all common thread profiles

- Solutions available for pitches up to 12.0 mm / 2 TPI

- Ultra Miniature and Miniature inserts for pitches as small as 0.5 mm

Carbide Grade(s):

THREADING INSERTS (FULL PROFILE, TYPE B)

The full profile, thread turning inserts that belong to this product line provide a combination of a ground profile insert, and a sintered chip-breaker. Unlike most other manufacturers’ inserts, this combination ensures consistent high quality thread, precise shape, and dimensions – while ensuring the chip flow.

Features:

- Solutions available for pitches up to 3.0 mm / 8 TPI

- Two different chip-breaker styles are used, in order to suit the different requirements of Internal and External threads

Carbide Grade(s):

THREADING INSERTS (FULL PROFILE, VERTICAL)

Full profile, thread turning inserts for vertical style cutting.

Features:

- Supports the following profiles: ISO / UN / Whitworth (55°) / NPT / BSPT / Acme / Trapez (DIN 103)

- Solutions available for pitches from 0.5 mm to 10.0 mm / 3 TPI

Carbide Grade(s):

THREADING INSERTS (FULL PROFILE, MULTITOOTH)

A new generation of thread turning inserts offers multiple cutting teeth per side, for maximum performance.

Features:

- 2 or 3 cutting teeth per insert side

- Solutions available for pitches from 1.0 mm to 3.0 mm / 8 TPI

Carbide Grade(s):

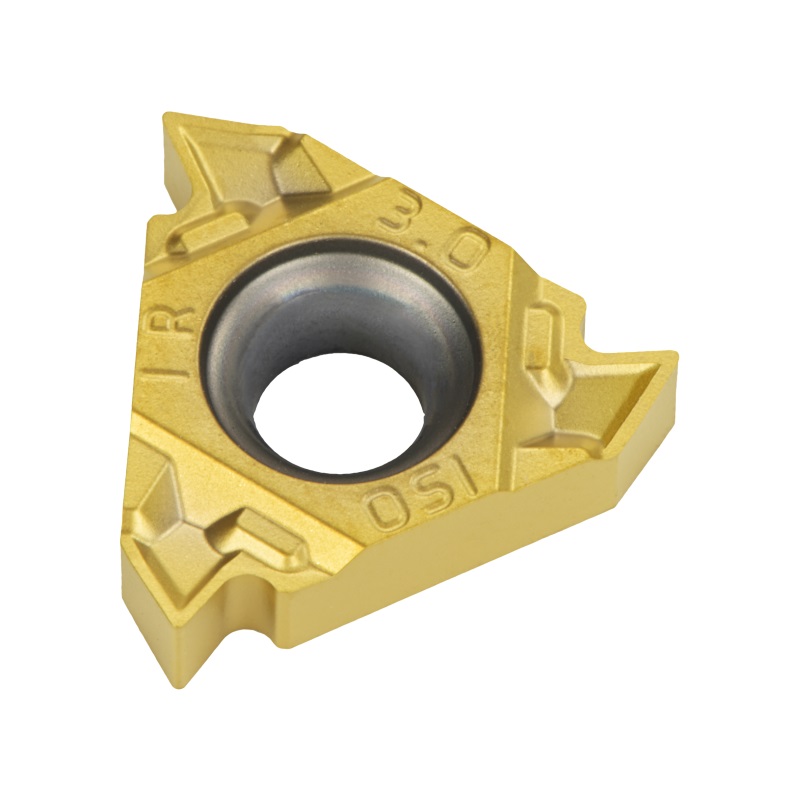

THREADING INSERTS (FULL PROFILE, TYPE K)

Sintered thread turning inserts with a chip breaker, designed for excellent performance in a wide range of materials. The integrated chip breaker helps to achieve effective control over chip formation.

Features:

- High edge-line security ensures dependable machining results

- Compatible with stock Carmex thread turning holders

Carbide Grade(s):

THREADING INSERTS (LARGE PROFILE)

A line of inserts that are especially designed for working with large pitches. They can be used only with holders from the Large Profile range.

Stock Profiles / Pitches (Metric Catalog):

- Trapez (DIN 103) / 14-24 mm

- Sagengewinde (DIN 513) / 9-16 mm

Stock Profiles / Pitches (Inch Catalog):

- Acme / 1.5-1 TPI

- Stub Acme / 1.5-1 TPI

- American Buttress / 2.5-1.25 TPI

We can also produce tooling for other profiles (such as DIN 20400) based on the customer’s specifications.

Carbide Grade(s):

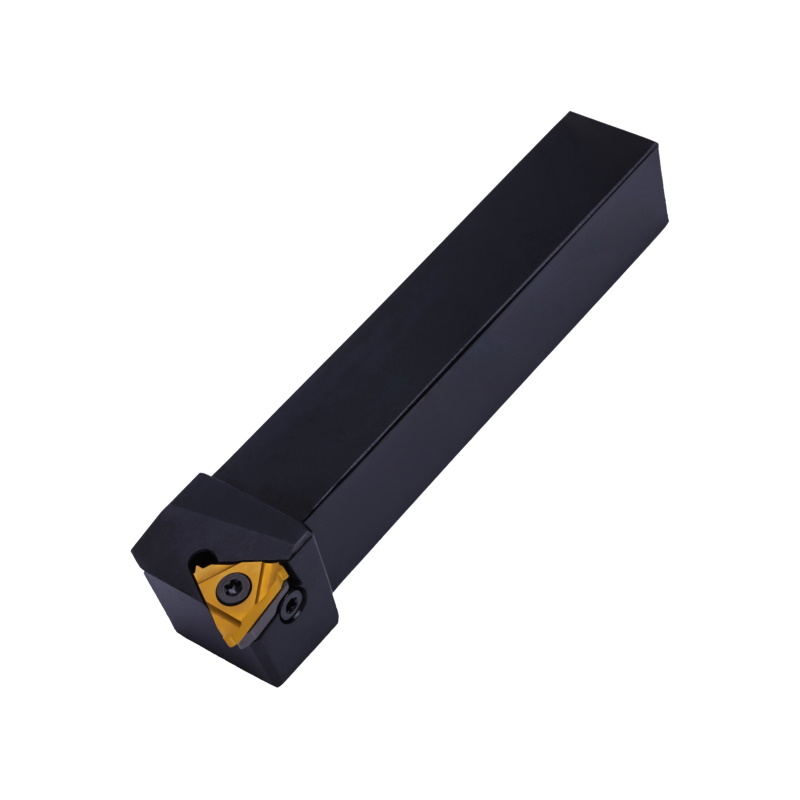

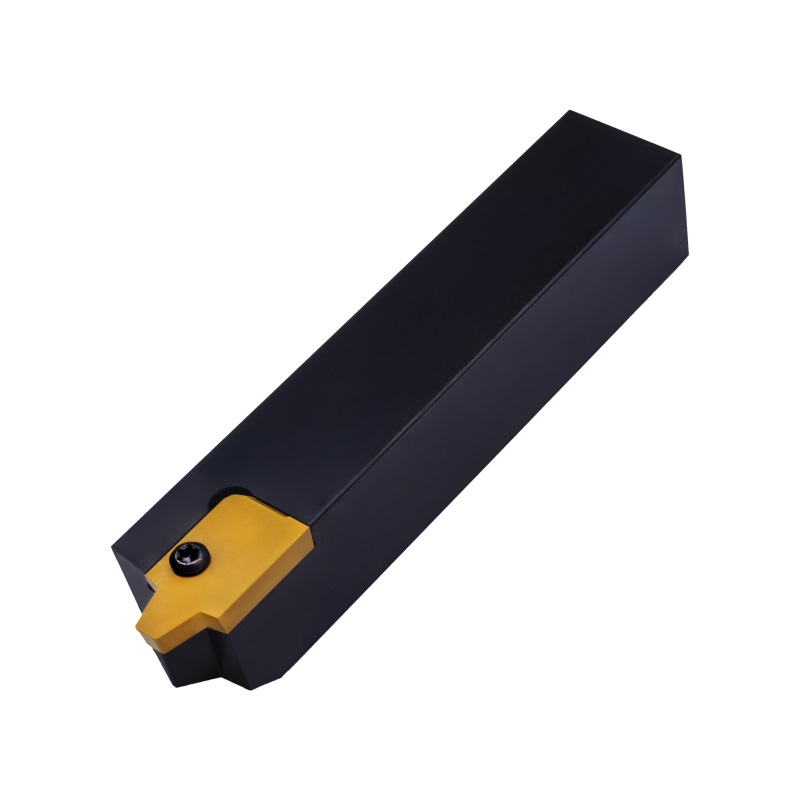

EXTERNAL HOLDERS

Tool holders for turning inserts. The holders that belong to the current line of products support only external threads/grooves.

Features:

- Left-hand and right-hand variants available

- Optional “U-Type” tool holders are compatible with “U-Type” thread turning inserts

- Most tool holders are made with a 1.5° helix angle. For other angles, please consult the helix angle chart.

OFF-SET (OFFSET) HOLDERS

Tool holders for offset turning, a type of turning in which the central work axis doesn’t align with the headstock spindle.

EXTERNAL HOLDERS WITH TOP CLAMP

External tool holders for turning inserts. These holders have an additional clamp for extra insert fastening security.

Features:

- Left-hand and right-hand variants available

- Most tool holders are made with a 1.5° helix angle. For other angles, please consult the helix angle chart.

Notes:

- Two clamping methods can be used: Screw / Top Clamp

- For DER 2525 M22 and DER 1000 M22, use the K21 torx key for C22 clamp

EXTERNAL VERTICAL HOLDERS

Tool holders for external, vertical style thread turning jobs.

Notes:

- These tool holders can only be used with vertical thread turning inserts – either partial profile, or full profile.

SLIM THROAT HOLDERS

Tool holders for external, vertical style thread turning jobs. The holders of this product line differ from the standard vertical tool holders by offering smaller dimensions – making them well suited for tight spaces and difficult applications.

Notes:

- These tool holders can only be used with vertical thread turning inserts – either partial profile, or full profile.

DROPHEAD HOLDERS

Tool holders for cutting external threads/grooves. These holders are specially designed to operate in an upside-down position, while keeping the height of the cutting edge at the same level as standard tool holders.

GANG HOLDERS

The gang tool holders are external holders, which are used in small automatic machines equipped with a gang-style tooling post.

Features:

- Left-hand and right-hand variants available

X-TREAM JET (EXTERNAL HOLDERS WITH INTERNAL COOLANT)

A unique product line of external tool holders equipped with an internal coolant – enabling a flow of coolant to the cutting edge. This reduces the temperature of the cutting edge while machining, helping to extend the life span of the tool. Additionally, the coolant fluid aids in removal of the chips during operation – improving the cutting performance.

Features:

- Two coolant connectors (using elbow fittings)

- Available with either ø4 mm or ø6 mm (the default) connectors

- Left-hand and right-hand variants available

- Coated holders provide abrasion resistance

- Tool holders are made with a 1.5° helix angle. For other angles, please consult the helix angle chart.

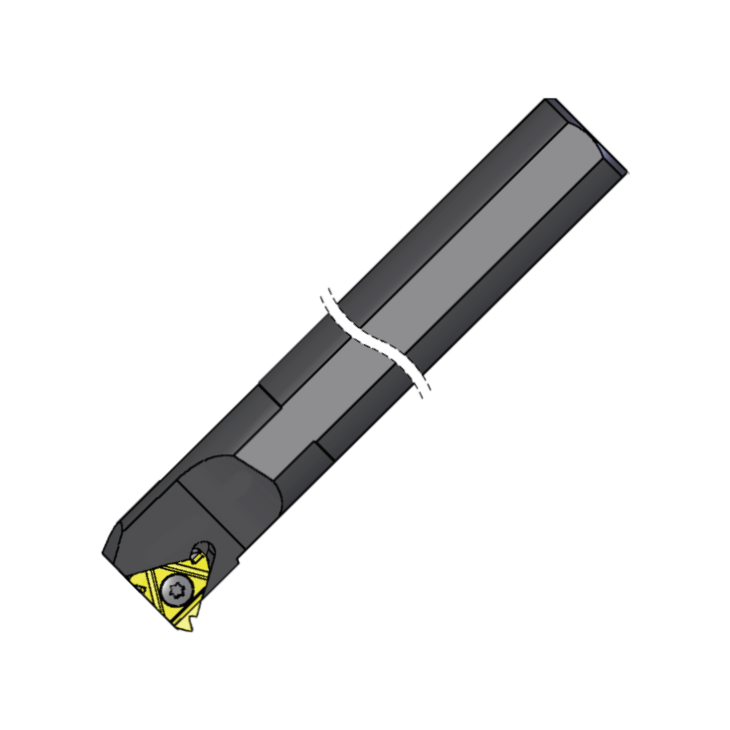

INTERNAL HOLDERS

Tool holders for turning inserts. The holders that belong to the current line of products support only internal threads/grooves.

Features:

- Left-hand and right-hand variants available

- Optional “U-Type” holders are compatible with “U-Type” thread turning inserts

- Most tool holders are made with a 1.5° helix angle. For other angles, please consult the helix angle chart.

INTERNAL HOLDERS WITH COOLANT BORE

Tool holders for cutting internal threads/grooves. These holders improve on the basic internal tool holders by adding an integrated coolant bore. The coolant fluid helps to evacuate the chips, which helps to maximize tool performance, as well as extend the life of the insert.

Features:

- Left-hand and right-hand variants available

- Most tool holders are made with a 1.5° helix angle. For other angles, please consult the helix angle chart.

INTERNAL HOLDERS WITH TOP CLAMP

Internal tool holders for turning inserts. These holders have an additional clamp for extra insert fastening security.

Features:

- Left-hand and right-hand variants available

- Most tool holders are made with a 1.5° helix angle. For other angles, please consult the helix angle chart.

Notes:

- Two clamping methods can be used: Screw / Top Clamp

- For DIR 0025 R22 and DIR 1000 R22, use the K21 torx key for C22 clamp

HOLDERS WITH 3.5° HELIX ANGLE

Tool holders for internal turning jobs. Unlike the standard holders that use a 1.5° helix angle, the tool holders that belong to the current product line use 3.5°.

Typically, one would consider using such a tool holder in case of a large-pitch thread with a relatively small diameter.

HOLDERS FOR SPECIAL APPLICATIONS

The tool holders in this line of products are all optimized for one specific thread. Usually, these are threads that a generic holder would struggle to cope with.

Features:

- Left-hand and right-hand variants available (except for SIR 0009 K08 and SIR 0354 K08)

Supported Threads:

- 1/2-13 UNC

- TR18x4

- TR20x4

- TR22x5

- TR40x7

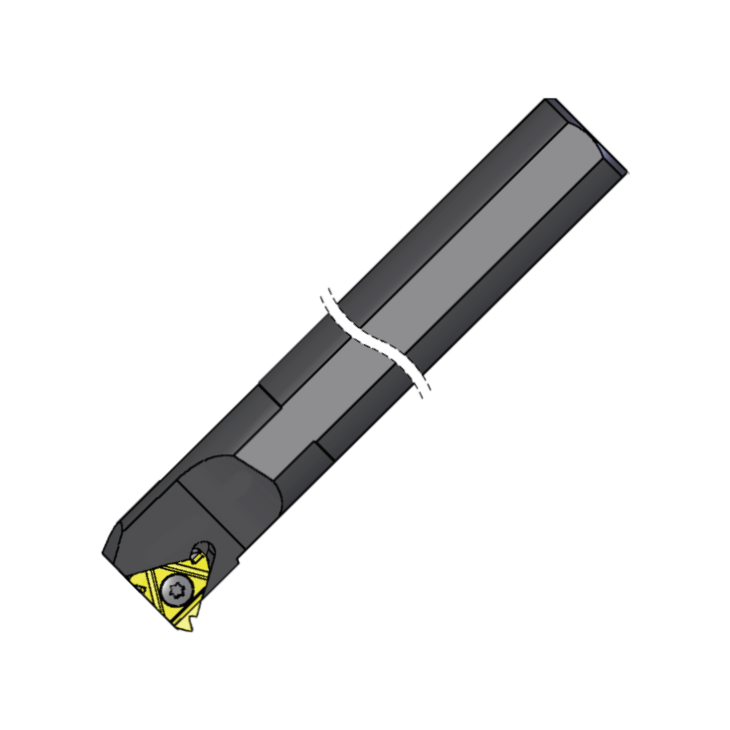

CARBIDE SHANK BARS

These carbide shank bars can be used to cut internal threads/grooves. They are especially well-suited for deep small bores with a long overhang, or for use in other situations, where chatter and deflection are expected. These bars have an integrated coolant bore, which helps with chip evacuation. This helps to maximize tool performance, as well as extend the life of the insert.

Features:

- Left-hand and right-hand variants available

INTERNAL VERTICAL HOLDERS

Tool holders for internal, vertical style thread turning jobs.

Features:

- Left-hand and right-hand variants available

Notes:

- These tool holders can only be used with vertical thread turning inserts – either partial profile, or full profile.

STAR ⌀22MM HOLDERS

A line of holders designed for use with a popular range of Swiss-type automatic lathes by Star® Micronics.

Features:

- Supports machines with a 22mm machining diameter

- Left-hand and right-hand variants available

QUICK CHANGE - EXTERNAL HOLDERS

The polygon shank tool holders of the Quick Change line are designed to be compliant with the ISO 26623-1 standard for toolholding systems. As such, they can be used with any coupling system that is based on the ISO 26623-1 standard, enabling quick & easy tool changes.

Features:

- The tool holders are interchangeable with solutions by other (leading) manufacturers

- Cooling through an internal bore is supported. This helps to evacuate the chips – aiding to maximize tool performance, as well as extend the life of the insert.

- A polygon taper ensures automatic radial centering, and even pressure distribution around the coupling

- Left-hand and right-hand variants available

- Based on a 1.4° tapered polygon shank design

QUICK CHANGE - INTERNAL HOLDERS

The polygon shank tool holders of the Quick Change line are designed to be compliant with the ISO 26623-1 standard for toolholding systems. As such, they can be used with any coupling system that is based on the ISO 26623-1 standard, enabling quick & easy tool changes.

Features:

- The tool holders are interchangeable with solutions by other (leading) manufacturers

- Cooling through an internal bore is supported. This helps to evacuate the chips – aiding to maximize tool performance, as well as extend the life of the insert.

- A polygon taper ensures automatic radial centering, and even pressure distribution around the coupling

- Left-hand and right-hand variants available

- Based on a 1.4° tapered polygon shank design

LARGE PROFILE - EXTERNAL HOLDERS

External tool holders designed to be used with inserts from the Large Profile line.

Features:

- Rigid clamping

- Left-hand variants available for certain profiles

LARGE PROFILE - INTERNAL HOLDERS

Internal tool holders designed to be used with inserts from the Large Profile line.

Features:

- Rigid clamping

- Left-hand variants available for certain profiles