Family Overview

A family of tools designed for working in small bores. These tools are made for the high-tech, medical & small components industries. They can be used in machining centers, or with conventional machines. All tools include through-coolant, enabling the cooling fluid to reach the cutting edge efficiently.

Features:

- Supports diameters as small as 1.0 mm (for some tools)

- The through-coolant aids in chip removal, helping to achieve a smooth cutting action

- Most turning applications supported (thread turning, grooving, chamfering, profiling, boring, and more)

- Variants for both right-hand and left-hand jobs available

The following product lines can used for thread turning:

MIR/L BARS (PARTIAL PROFILE)

A versatile product line of partial-profile threading bars.

Features:

- Compatible with 60° and 55° profiles

- Solutions available for pitches from 0.25 mm / 100 TPI to 2.0 mm / 13 TPI

- Minimum bore diameter: 1.2 mm / 0.05 inch

- Both right-hand and left-hand versions available

Carbide Grade(s):

MIR/L BARS (FULL PROFILE)

A product line of full-profile threading bars.

Features:

- Solutions available for threads as small as ISO M3 x 0.5 and 6-32 UNC

- Minimum bore diameter: 2.3 mm / 0.09 inch

- Both right-hand and left-hand versions available

Carbide Grade(s):

BAR HOLDERS

The basic line of bar holders for bars from the Tiny Tools family.

Features:

- Compatible with all currently existing Tiny bars (diameters from 3.0 mm to 10.0 mm)

BAR HOLDERS (WITH FRONT COOLANT ATTACHMENT)

These bar holders provide a modest variation over the basic bar holders, by offering a slightly different geometry, as well as adding a coolant attachment in the front of the holder.

Features:

- Compatible with bars with diameters from 3.0 mm to 8.0 mm

BAR HOLDERS FOR STAR SWISS MACHINES

External turning holders for bars from the Tiny Tools family; Specially designed for operations on Swiss-type CNC lathes by Star® Micronics. The Tiny bar can be gripped in two directions, allowing for a turning operation on both X and Y axis.

Features:

- Designed with internal coolant to the cutting edge

- Coated holders provide abrasion resistance

- Compatible with bars with diameters from 3.0 mm to 10.0 mm

CIM - FAST CLAMPING SYSTEM

The innovative CIM clamping system provides high precision and repeatability, as well as a fast and simple way to change the Tiny Tools bar – without removing the CIM holder, or engaging in additional tool setup. It includes an internal tool indexing mechanism which indexes the tool in the correct position, as well as strong and rigid collet clamping for high stability.

For additional information. you can view a diagram of the clamping system, or read the instructions for use (IFU).

Features:

- No screws required

- Internal coolant through the CIM holder and the Tiny Tools bar to the cutting edge

- Holders with 3 clamping flats on the shank for maximum flexibility

- Compatible with bars with diameters from 4.0 mm to 6.0 mm

SQUARE SHANK HOLDERS (VERTICAL)

A product line of bar holders with square shanks; To be used where such a shank is required (typically: Automatic/Swiss-type machines, etc.). These holders were designed to be used with a vertical lathe.

Features:

- Compatible with bars with diameters from 3.0 mm to 6.0 mm

SQUARE SHANK HOLDERS (RIGHT-HAND)

A product line of bar holders with square shanks; To be used where such a shank is required (typically: Automatic/Swiss-type machines, etc.). These holders were developed for right-hand machining.

Features:

- Compatible with bars with diameters from 3.0 mm to 6.0 mm

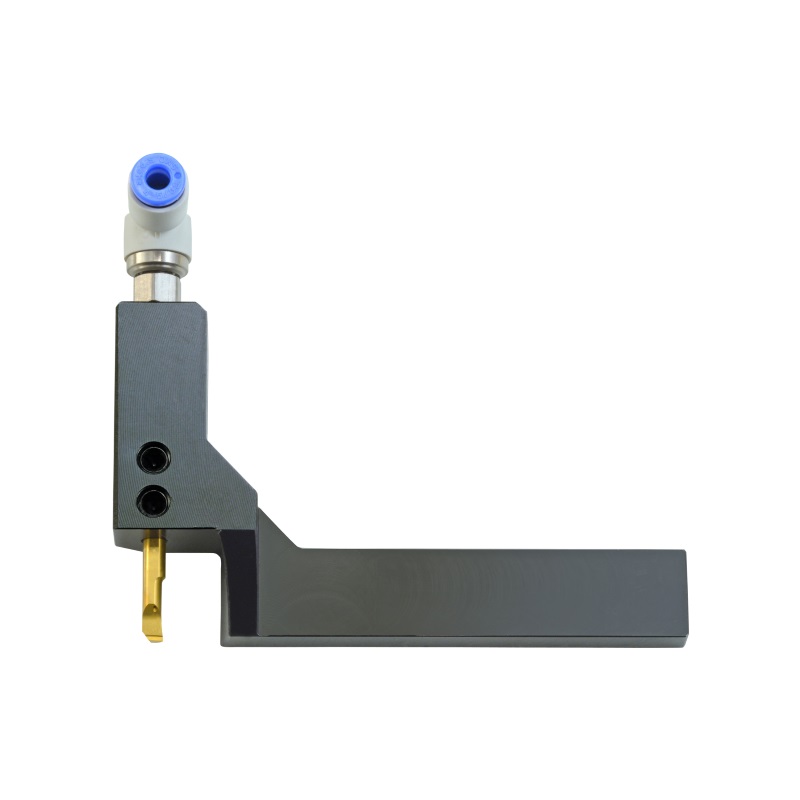

SQUARE SHANK HOLDERS (WITH KNEE)

A product line of bar holders with square shanks; To be used where such a shank is required (typically: Automatic/Swiss-type machines, etc.). This variant comes in a “knee” form.

Features:

- Compatible with bars with diameters from 3.0 mm to 6.0 mm