Family Overview

In many companies, Swiss-type machines are becoming a popular alternative to large lathes and machining centers. As a result, we developed a family of indexable tools designed for use with automatic lathes and Swiss-type machines. These tools enable high-volume, cost-efficient machining of external grooving, back/front turning, profiling, thread turning, parting, and general turning applications.

Features:

- Grounded cutting edges

- The inserts can be indexed directly on the machine

- Coated holders provide abrasion resistance

The following product lines can used for thread turning:

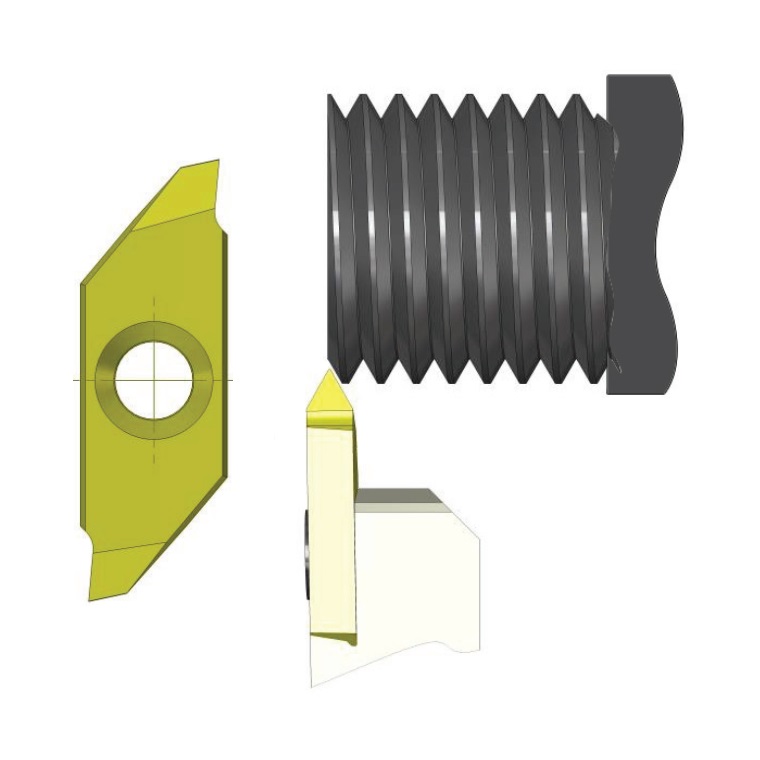

POLYGON THREADING INSERTS (PARTIAL PROFILE)

A product line of partial-profile threading inserts, suitable for cutting external threads. These inserts (like all polygon inserts) are designed specially for the production of small parts.

Features:

- Inserts available for 60° and 55° profiles

- Solutions available for pitches from 0.25 mm / 100 TPI to 3.0 mm / 8 TPI

- Variants for both right-hand and left-hand cutting exist

Carbide Grade(s):

POLYGON THREADING INSERTS (FULL PROFILE)

A line of full-profile threading inserts, engineered to enable efficient machining of external threading applications. These inserts (like all polygon inserts) are designed specially for the production of small parts.

Features:

- Inserts available for the ISO and UN threads

- Solutions available for pitches from 0.5 mm / 56 TPI to 1.5 mm / 24 TPI

- Variants for both right-hand and left-hand cutting exist

Carbide Grade(s):

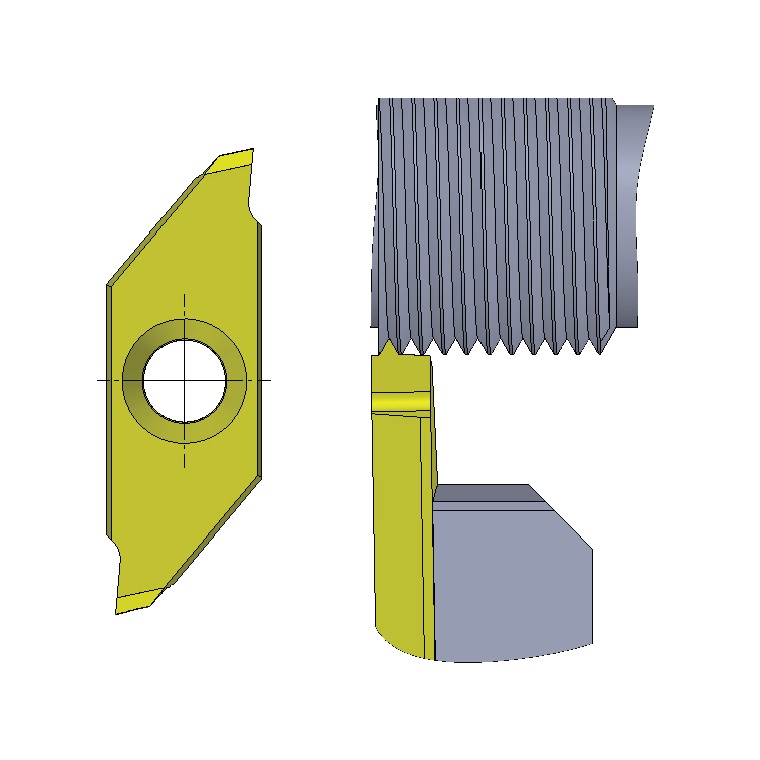

3 CUTTING EDGES THREADING INSERTS (PARTIAL PROFILE)

The basic product line of partial-profile threading inserts for machining external threads on Swiss-type machines. All inserts of this product line feature three cutting edges, helping to improve productivity.

Features:

- Inserts available for 60° and 55° profiles

- Solutions available for pitches from 0.5 mm / 48 TPI to 3.0 mm / 8 TPI

- Variants for both right-hand and left-hand cutting exist

Carbide Grade(s):

3 CUTTING EDGES THREADING INSERTS (FULL PROFILE)

A prime product line of full-profile threading inserts. The inserts in this line were created to machine external threading applications on Swiss-type machines. They all feature three cutting edges, thus improving the productivity.

Features:

- Inserts available for ISO and UN profiles

- Solutions available for pitches from 0.5 mm / 72 TPI to 1.75 mm / 20 TPI

- Variants for both right-hand and left-hand cutting exist

Carbide Grade(s):

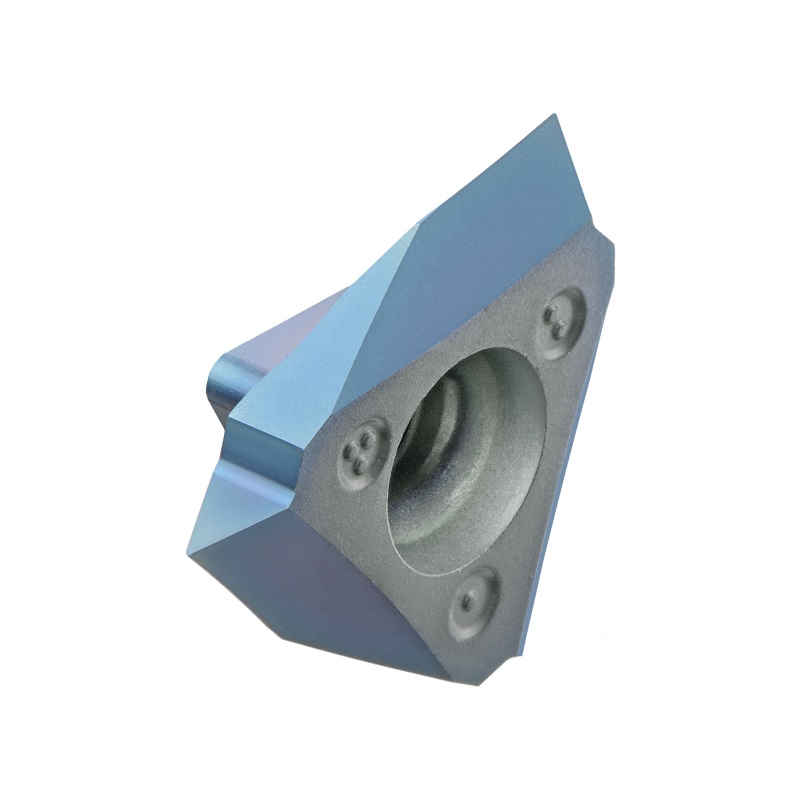

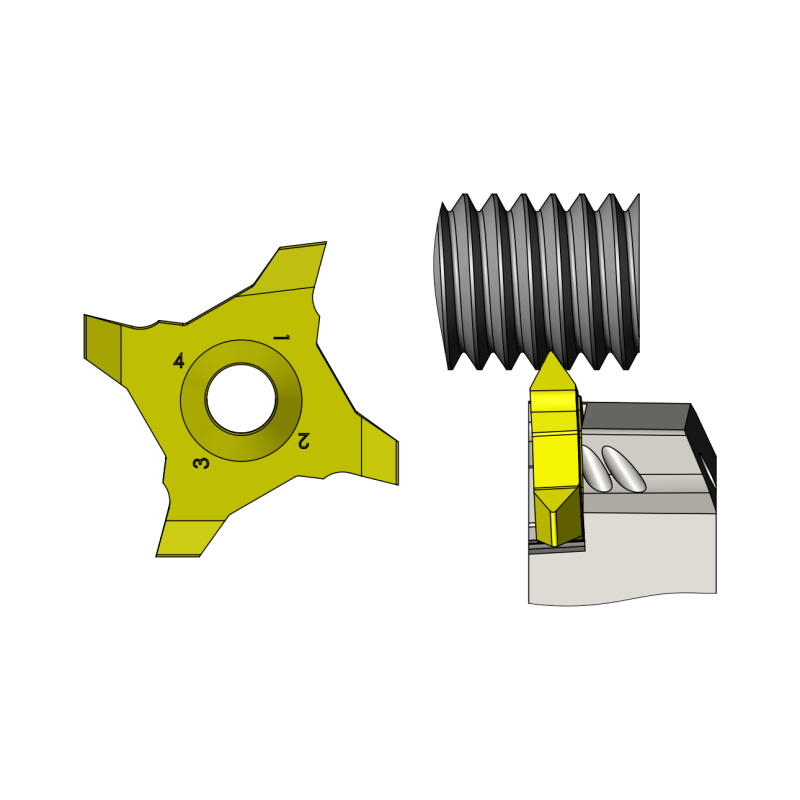

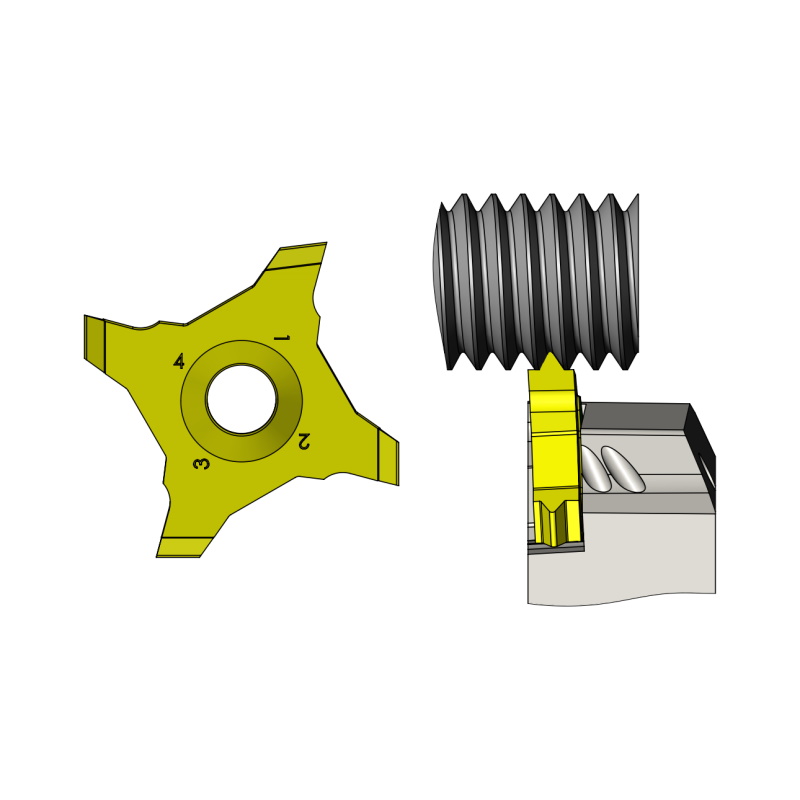

G4 (4 CUTTING EDGES) THREADING INSERTS (PARTIAL PROFILE)

A line of partial-profile threading inserts, designed to machine external threading applications. They are compatible with a large range of diameters: From very thin-walled applications – to diameters as large as 100 mm. These inserts come with four cutting edges, which enables high productivity to be achieved at a reasonable cost.

Features:

- The unique shape of the insert and the holder pocket helps to achieve stable clamping

- Inserts available for 60° and 55° profiles

- Solutions available for pitches from 0.25 mm / 100 TPI to 3.0 mm / 8 TPI

- Variants for both right-hand and left-hand cutting exist

Carbide Grade(s):

G4 (4 CUTTING EDGES) THREADING INSERTS (FULL PROFILE)

A product line of full-profile threading inserts, designed to cut external ISO & UN threads. The four cutting edges enable high productivity to be achieved at a reasonable cost.

Features:

- The unique shape of the insert and the holder pocket helps to achieve stable clamping

- Variants for both right-hand and left-hand cutting exist

Carbide Grade(s):

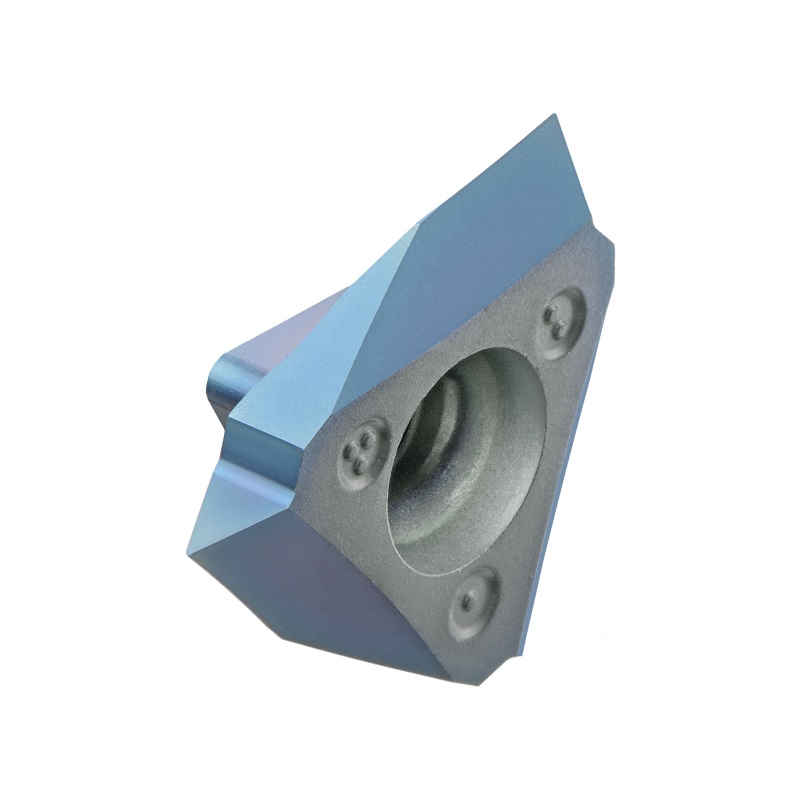

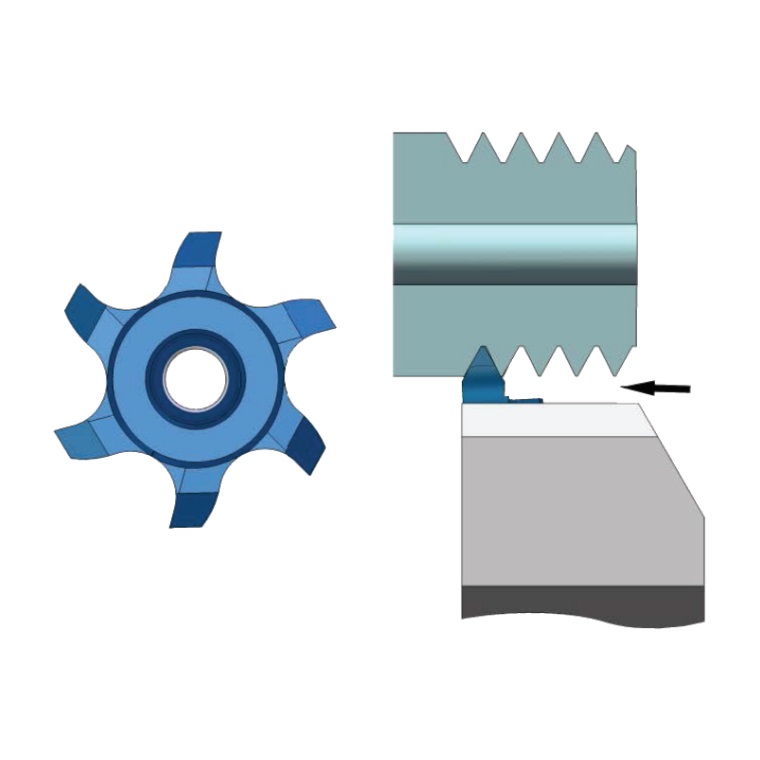

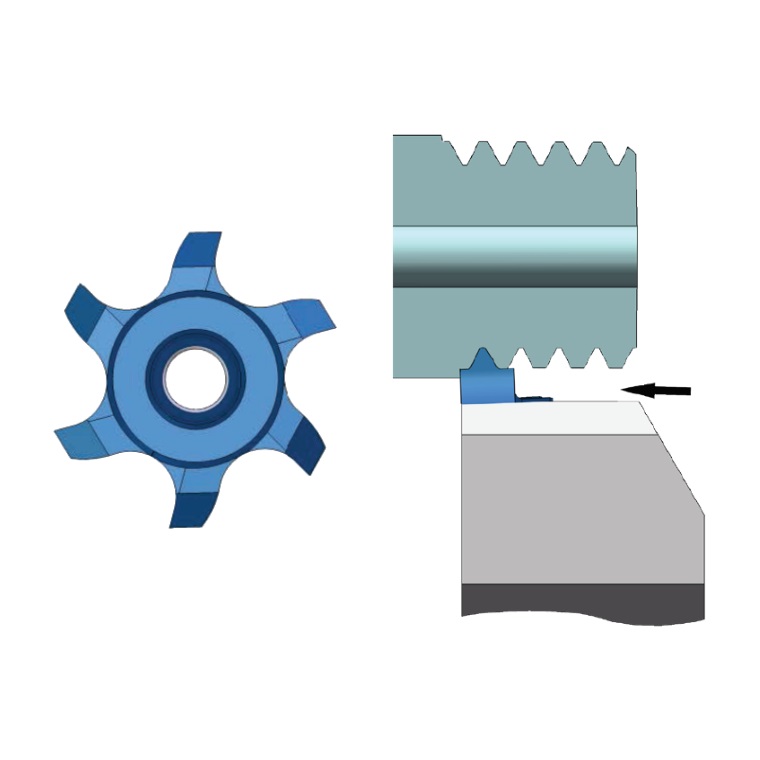

G6 (6 CUTTING EDGES) THREADING INSERTS (PARTIAL PROFILE)

These partial-profile threading inserts were designed for machining external threads. Like all G6 inserts, these inserts are compatible with a wide variety of diameters: From very small, thin-walled applications – to diameters as large as 60 mm. The six cutting edges help these inserts to achieve outstanding productivity, while maintaining a favorable cost-effectiveness ratio.

Features:

- Strong and stable clamping due to the unique insert shape

- Inserts available for 60° and 55° profiles

- Solutions available for pitches from 0.5 mm / 48 TPI to 3.0 mm / 8 TPI

- Variants for both right-hand and left-hand cutting exist

Carbide Grade(s):

G6 (6 CUTTING EDGES) THREADING INSERTS (FULL PROFILE)

The full-profile threading inserts of this product line are capable of machining external ISO & UN threads, in several common pitches. Their six cutting edges allow for substantial upgrades in throughput.

Features:

- Strong and stable clamping due to the unique insert shape

- Variants for both right-hand and left-hand cutting exist

Carbide Grade(s):

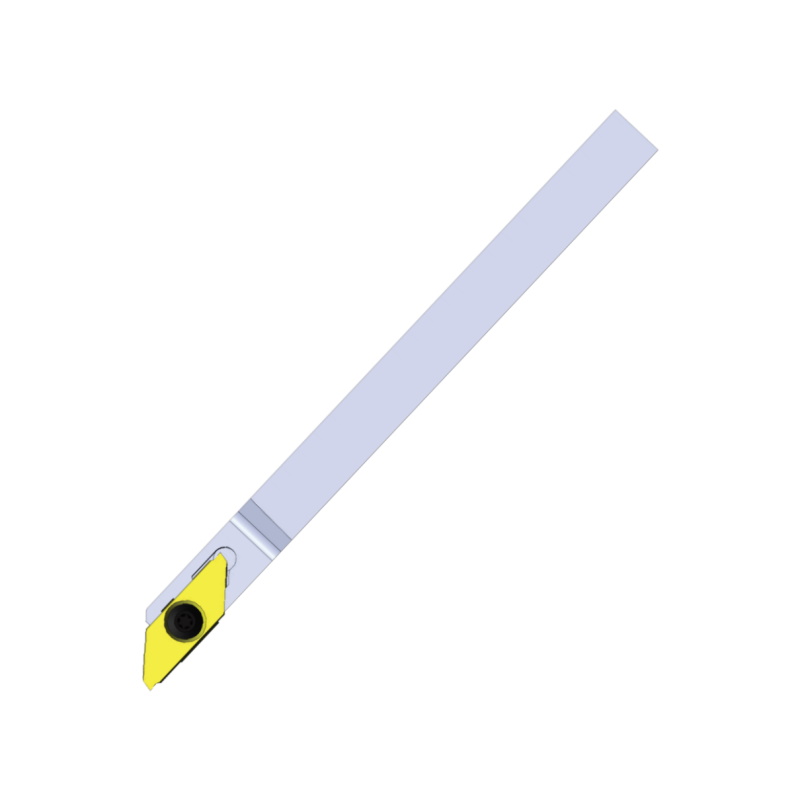

POLYGON TOOL HOLDERS (WITHOUT COOLANT)

A product line of external holders for Polygon inserts from the Swiss-Line family. These holders do not support through-coolant.

Features:

- Each Polygon insert is compatible with every holder in the line (“one size fits all”)

- Variants available for right-hand and left-hand applications

POLYGON TOOL HOLDERS (WITH COOLANT)

External holders for Polygon inserts from the Swiss-Line family. These holders provide an upgrade over the basic Polygon holders, by including support for through-coolant (via the included coolant connector).

Features:

- The coolant connector allows for fast attachment on the machine

- Each Polygon insert is compatible with every holder in the line (“one size fits all”)

- Variants available for right-hand and left-hand applications

POLYGON TOOL HOLDERS (SLIM)

A line of external holders for Polygon inserts from the Swiss-Line family, without through-coolant support. The slimmer bodies of these holders make them a great choice for small applications.

Notes:

- Unlike in the other product lines, the holders of this line only support Left-hand jobs.

3 CUTTING EDGES TOOL HOLDERS (19/20 MM)

This product line contains external tool holders designed to work with Swiss-Line inserts with 3 cutting edges (sized 19 mm and 20 mm). Similar to other Swiss-Line holders, they too have been developed for the purposes of machining external turning applications in Swiss-type machines. They include support for through-coolant(*) (via the included coolant connector), which aids in prevention of potentially damaging chip buildup.

(*) Except for GER 0816 K and GEL 0816 K

Features:

- The coolant connector allows for fast attachment on the machine

- Variants available for right-hand and left-hand applications

3 CUTTING EDGES TOOL HOLDERS (19/20 MM, SLIM)

The external tool holders in this product line work in conjunction with 3 cutting edge inserts from our Swiss-Line family (only those with sizes of 19 mm and 20 mm). They differ from the basic “3 cutting edges” holders, by offering slimmer bodies and necks – making them well suited for smaller applications (though of course they can be used with standard applications as well). Just like with all other Swiss-Line holders, the main purpose of these holders is the machining of external turning applications in Swiss-type machines. They come with an integrated coolant connector which enables through-cooling to be used.

Features:

- The coolant connector allows for fast attachment on the machine

- Variants available for right-hand and left-hand applications

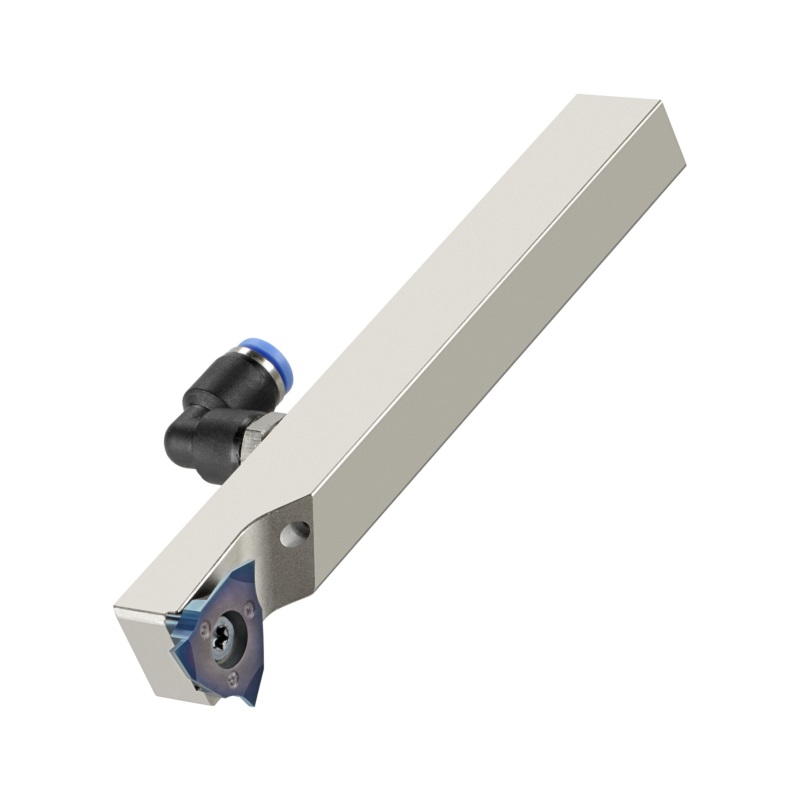

G4 (4 CUTTING EDGES) TOOL HOLDERS

External holders for the G4 inserts from the Swiss-Line family. Designed for machining of external turning applications in Swiss-type machines, these holders include support for through-coolant(*) (via the included coolant connector). This improves the evacuation of the chips that form during the machining process, thus prolonging the tool life, and increasing the performance.

(*) Except for G4ER/L 1212 K

Features:

- Each G4 insert can be used with every holder in the line (“one size fits all”)

- Variants available for right-hand and left-hand applications

G6 (6 CUTTING EDGES) TOOL HOLDERS

A product line of external holders for G6 inserts from the Swiss-Line family. Like all Swiss-Line holders, these holders are designed for machining of external turning applications in Swiss-type machines. They include support for through-coolant(*) (via the included coolant connector), helping to evacuate the chips as they are created – thus preventing a potentially damaging chip buildup.

(*) Except for G6ER/L 1212 K, TGER/L 1212 K, and G6ER/L 0500 K

Features:

- The coolant connector allows for fast attachment on the machine

- Each G6 insert is compatible with every holder in the line (“one size fits all”)

- Variants available for right-hand and left-hand applications