Family Overview

A family of vertical inserts and tool holders, designed for long threads – or applications that require an over-hang. They can be used for threading, chamfering, grooving, boring, profiling, and back turning applications. All tools include through-coolant, enabling the cooling fluid to reach the cutting edge efficiently.

Features:

- Supports diameters starting from 8.0 mm (for some tools)

- Quick indexing

- Most profiles of Tiny Tools bars are available

The following product lines can used for grooving:

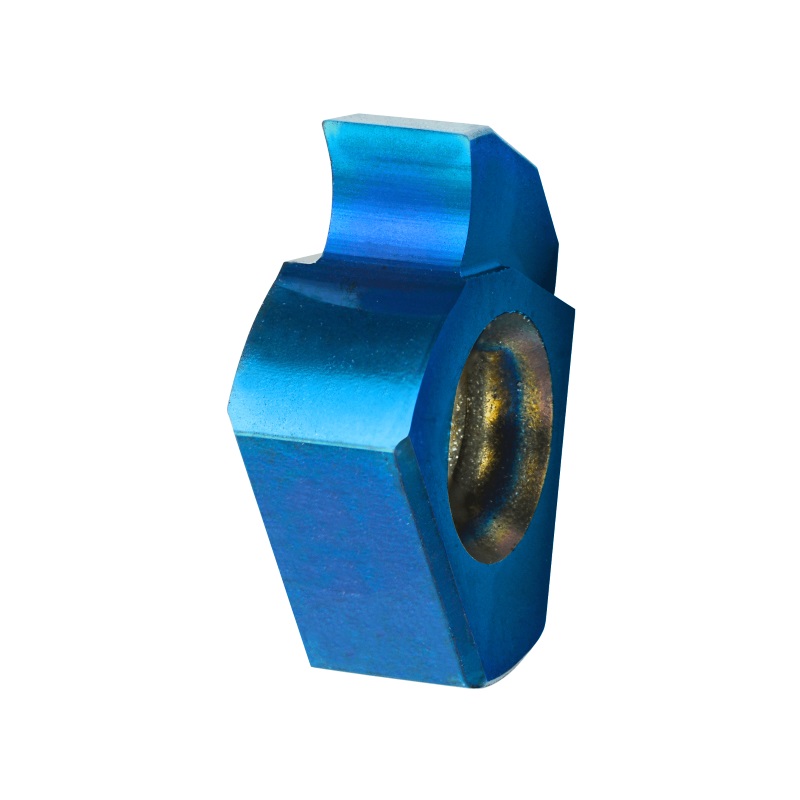

GROOVING INSERTS

The inserts in this product line were designed for cutting grooves.

Features:

- Minimum bore diameter from: 9.4 mm / 0.37 inch

Carbide Grade(s):

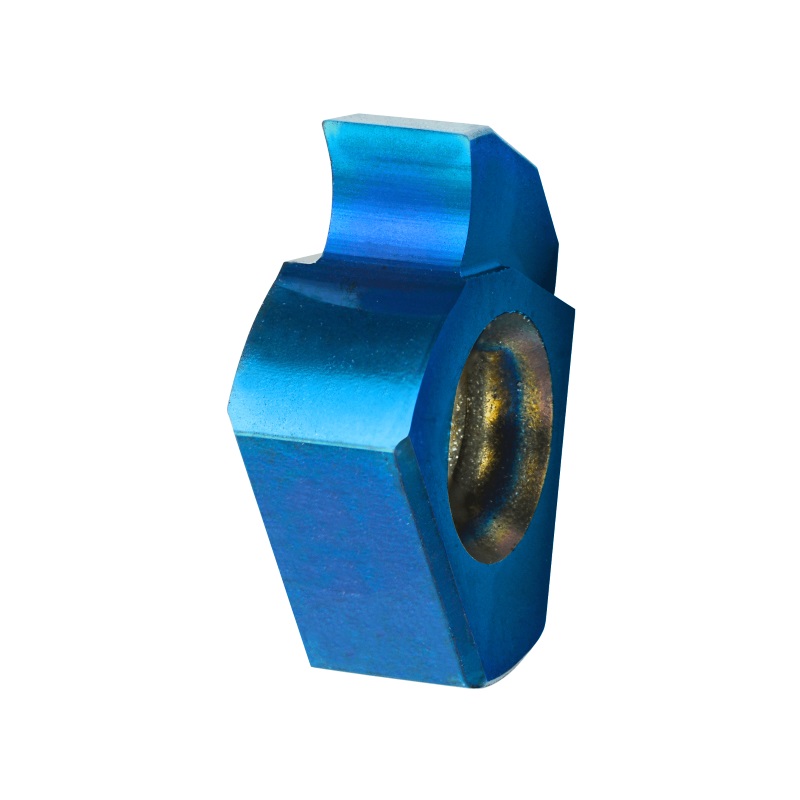

GROOVING INSERTS (CIRCLIP RING GROOVES)

Grooving inserts, designed for the production of circlip rings. The groove widths, and other dimensions of these inserts are specially optimized towards the production of circlip rings (also known as C-clips, snap rings, or shaft retaining rings), based on the DIN 471/472 standard.

Features:

- Minimum bore diameter: 8.8 mm

- Nominal groove width: From 0.7 mm

Carbide Grade(s):

FULL RADIUS GROOVING INSERTS

A variant of the regular grooving inserts, that produce round (“full radius”) grooves. In addition to the grooving applications, it can also be used for general turning jobs.

Features:

- Minimum bore diameter from: 8.4 mm / 0.33 inch

Carbide Grade(s):

FACE GROOVING INSERTS

A product line of inserts optimized for machining face grooving applications.

Features:

- Variants for both internal and external jobs available

- Internal minimum bore diameter: 14.0 mm / 0.55 inch

- External minimum bore diameter: 12.0 mm / 0.47 inch

Carbide Grade(s):

FULL RADIUS FACE GROOVING INSERTS

A variant of the regular face grooving inserts, that produce round (“full radius”) grooves.

Features:

- Variants for both internal and external jobs available

- Internal minimum bore diameter: 14.0 mm / 0.55 inch

- External minimum bore diameter: 12.0 mm / 0.47 inch

Carbide Grade(s):

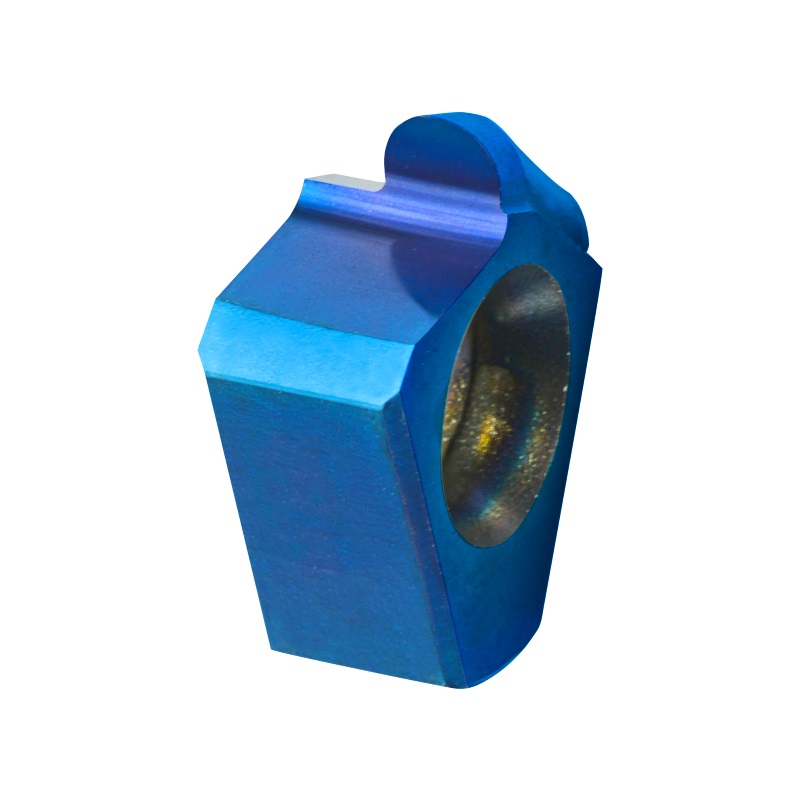

BACK TURNING INSERTS

A product line of inserts developed for the purpose of machining back turning jobs. On top of that, the inserts can also be used to complete grooving and profiling applications, as well as general turning applications.

Features:

- Minimum bore diameter from: 9.4 mm / 0.37 inch

Carbide Grade(s):

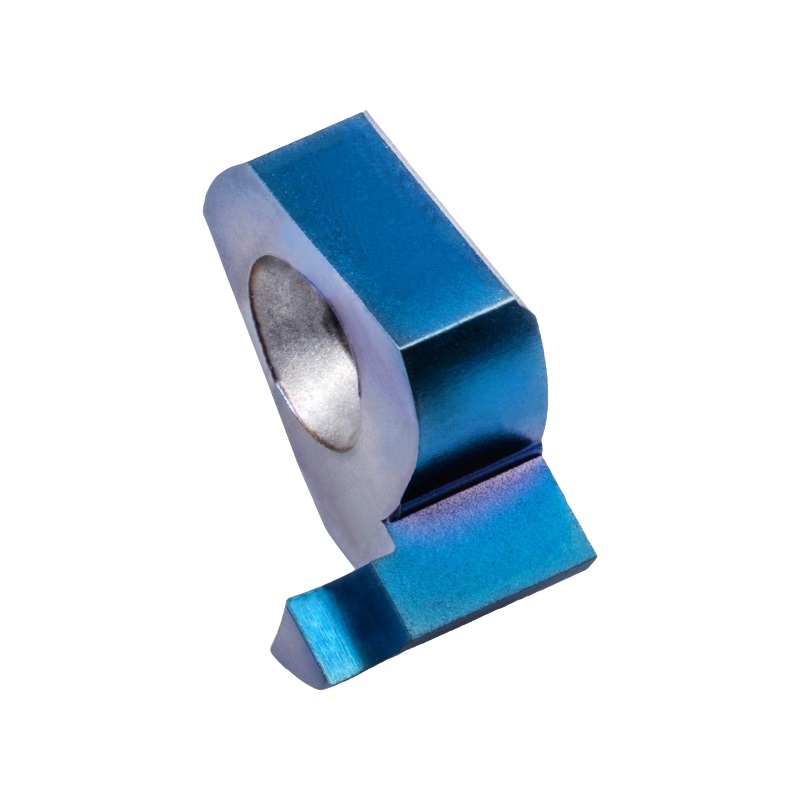

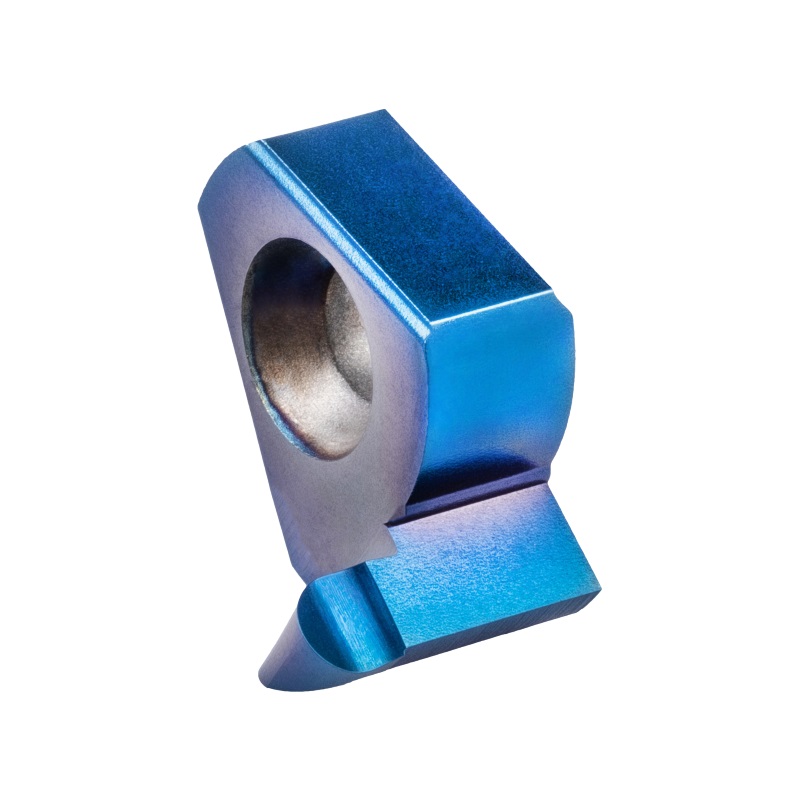

CARBIDE SHANK TOOL HOLDERS

An extensive product line of holders for inserts from the Mini Tools family.

Features:

- Excellent vibration resistance

- Compatible with both T8 and T10 insert types

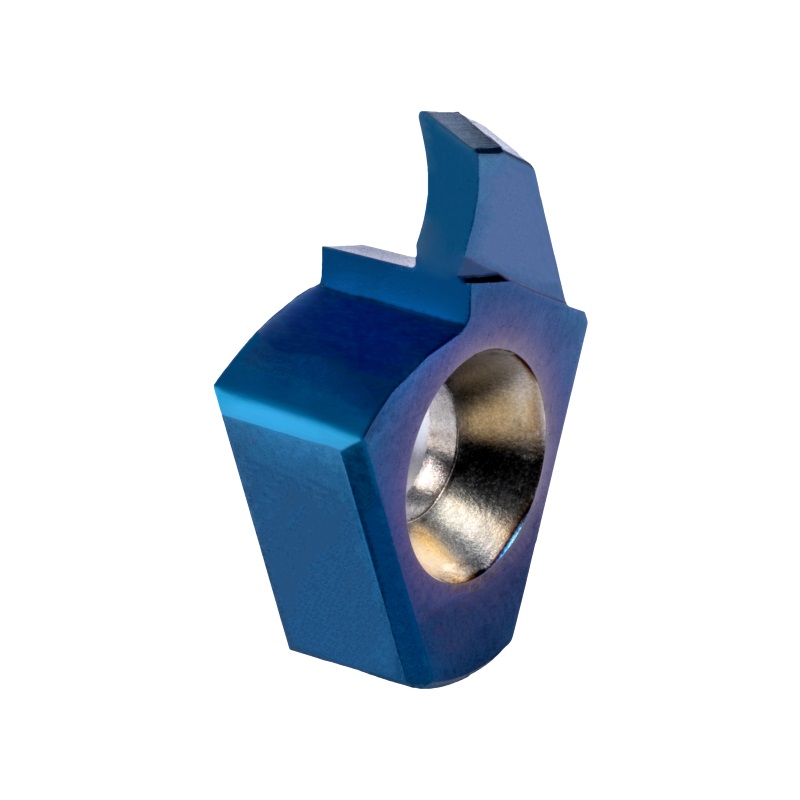

STEEL TOOL HOLDERS

A line of steel holders for inserts from the Mini Tools family.

Features:

- Compatible only with the T10 insert type