Family Overview

The polycrystalline cubic boron nitride (CBN) inserts offer a high level of hardness, as well as thermal shock resistance. Although CBN’s exceptional toughness/hardness is still less than the diamond-based materials, it provides superior resistance to high temperatures. They can be used at very high cutting speeds.

This makes CBN inserts the ideal cutting material for machining of hardened steels (45-72 HRC) of any kind: Case hardened steel, tool steel, heat treated steel, etc. Additionally, it is also well suited to the machining of applications in which carbide and ceramic cutting tools often reach their limits, such as cast materials, and special alloys. They are compatible with standard tool holders by other, leading manufacturers.

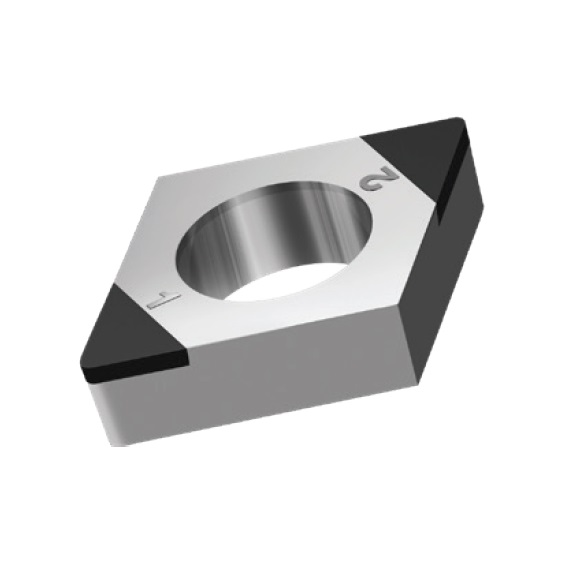

CCGW INSERTS

A line of inserts with a 80° cutting corner angle, and two cutting tips. These inserts have a neutral rake angle, and a relief angle of 7°.

Features:

- Wiper geometry versions available

Notes:

- The CCGW 060201 and CCGW 09T301 inserts are only available in CH25 and CK65 grades

- The CCGW 09T302-W wiper insert is only available in CP25 / CP45 / CK65 / CK85 grades

Carbide Grade(s):

CDGW INSERTS

A line of inserts with a 80° cutting corner angle, and two cutting tips. These inserts have a neutral rake angle, and a relief angle of 15°.

Carbide Grade(s):

CNGA INSERTS

A line of inserts with a 80° cutting corner angle, and two cutting tips. These inserts have a neutral rake angle, and a relief angle of 0°.

Features:

- Wiper geometry versions available

Carbide Grade(s):

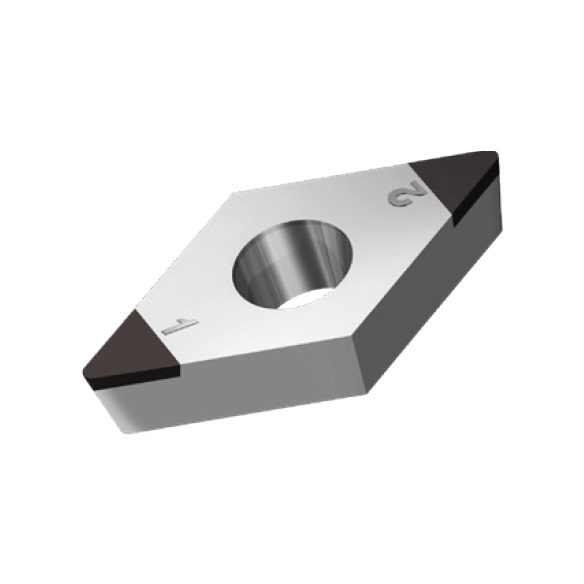

DCGW INSERTS

A line of inserts with a 55° cutting corner angle, and two cutting tips. These inserts have a neutral rake angle, and a relief angle of 7°.

Features:

- Wiper geometry versions available

Note:

- The DCGW 070201 and DCGW 11T301 inserts are only available in CH25 and CK65 grades

Carbide Grade(s):

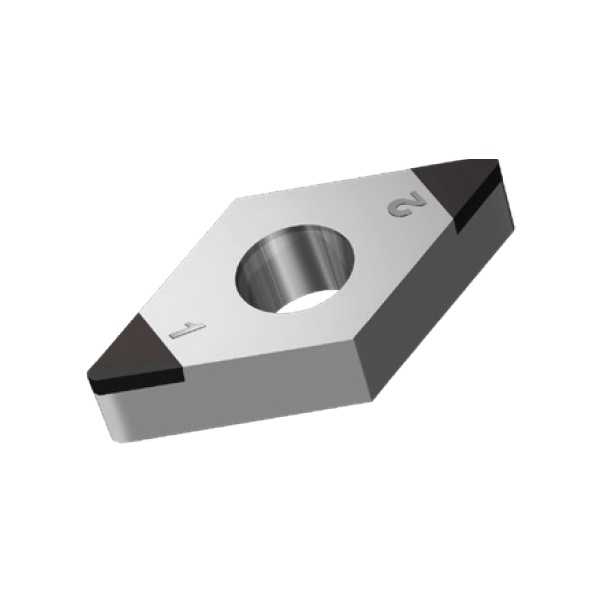

DNGA INSERTS

A line of inserts with a 55° cutting corner angle, and two cutting tips. These inserts have a neutral rake angle, and a relief angle of 0°.

Features:

- Wiper geometry versions available

Note:

- The DNGA 150401 insert is only available in CH25 and CK65 grades

Carbide Grade(s):

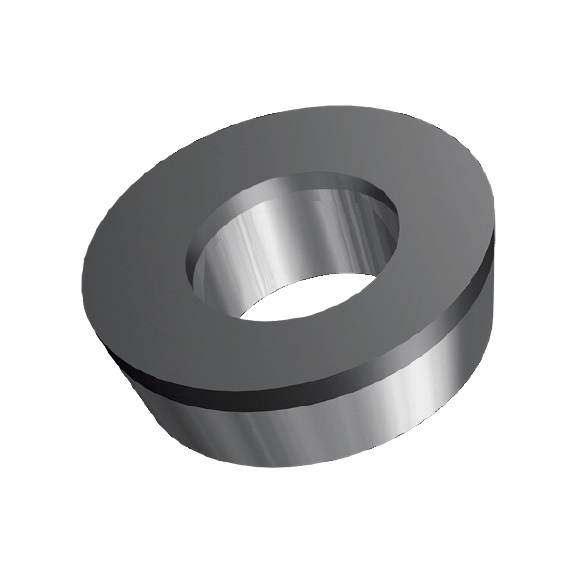

RCGW INSERTS

A line of round, full-face inserts with a relief angle of 7°.

Carbide Grade(s):

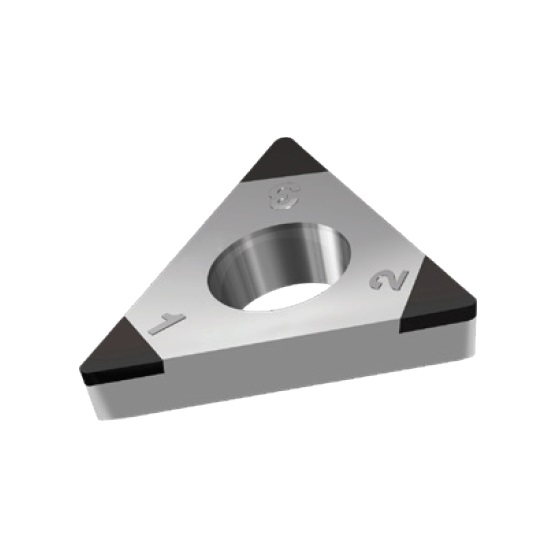

TCGW INSERTS

A line of inserts with a 60° cutting corner angle, and three cutting tips. These inserts have a neutral rake angle, and a relief angle of 7°.

Note:

- The TCGW 090201 and TCGW 110201 inserts are only available in CH25 grade

Carbide Grade(s):

TNGA INSERTS

A line of inserts with a 60° cutting corner angle, and three cutting tips. These inserts have a neutral rake angle, and a relief angle of 0°.

Carbide Grade(s):

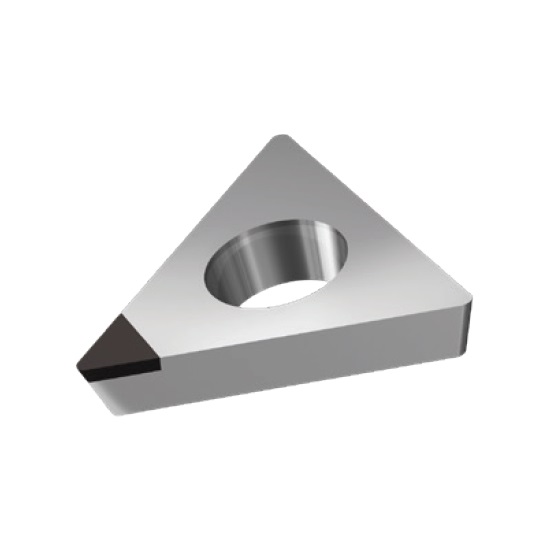

TPGW INSERTS

A line of inserts with a 60° cutting corner angle, and a single cutting tip. These inserts have a neutral rake angle, and a relief angle of 11°.

Carbide Grade(s):

VCGW INSERTS

A line of inserts with a 35° cutting corner angle, and two cutting tips. These inserts have a neutral rake angle, and a relief angle of 7°.

Note:

- The VCGW 070201, VCGW 110301 and VCGW 160401 inserts are only available in CH25 and CK65 grades

Carbide Grade(s):

VNGA INSERTS

A line of inserts with a 35° cutting corner angle, and two cutting tips. These inserts have a neutral rake angle, and a relief angle of 0°.

Carbide Grade(s):

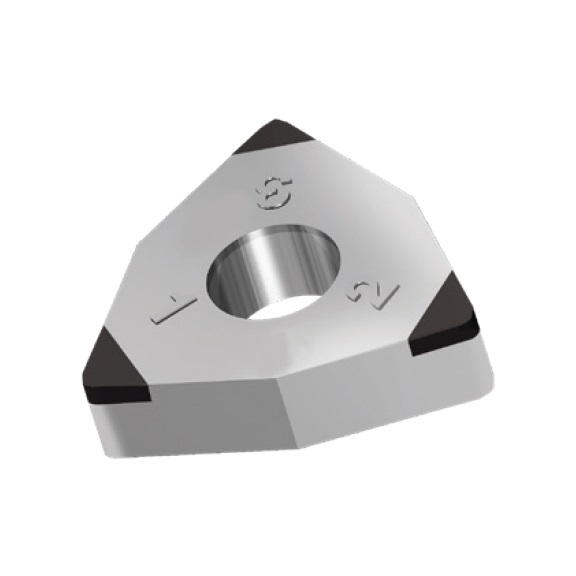

WCGW INSERTS

A line of inserts with a 80° cutting corner angle, and three cutting tips. These inserts have a neutral rake angle, and a relief angle of 7°.

Carbide Grade(s):

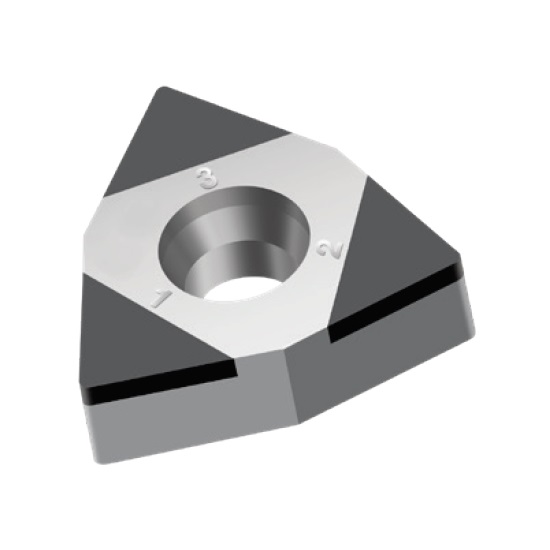

WNGA INSERTS

A line of inserts with a 80° cutting corner angle, and three cutting tips. These inserts have a neutral rake angle, and a relief angle of 0°.

Carbide Grade(s):