Family Overview

The Mini Mill-Thread family is comprised of small solid-carbide thread mills. The tools in the family have been specially designed for the production of threads in very small bores. In order to achieve this, we’ve employed unique tool designs, accurate geometries, and quality coatings.

Features:

- Low cutting forces thanks to the short profile

- Can work under high cutting speeds, resulting in shorter machining times

- Threading up to shoulder in blind holes

Our range of Mini Mill-Thread tools consists of the following lines:

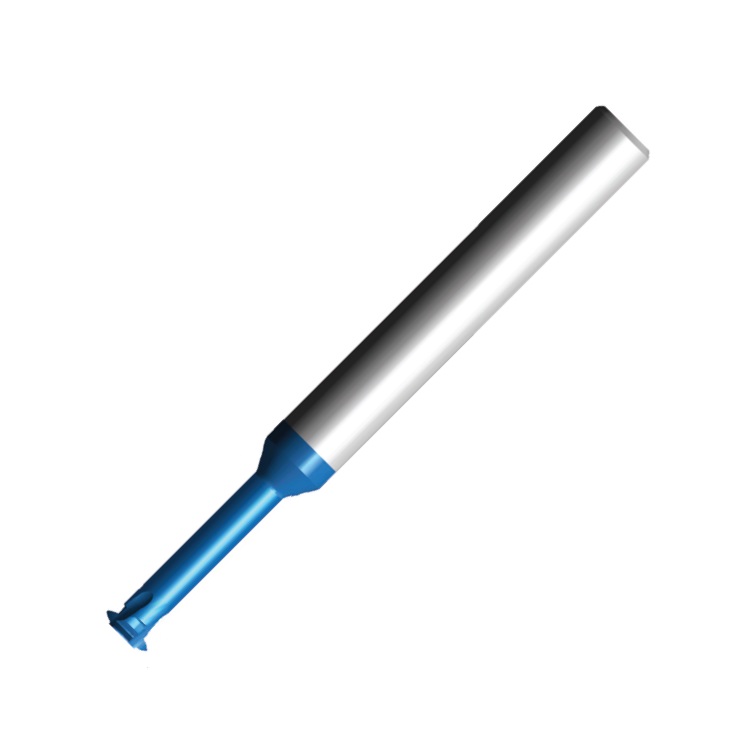

MTS - THREAD MILLS WITHOUT INTERNAL COOLANT

The full-profile thread mills in this product line are compatible only with Internal threads (with the exception of tools for the G55° thread profile). They can be used to machine Titanium, surgical stainless steels, and hardened materials (up to 45 HRC) – as well as for general purpose threading.

Features:

- Supports threads as small as ISO M1 x 0.25, and 0-80 UNF

- The thread depth can be up to 5 x Thread Diameter (for some tools)

- Multi (3-5) flutes

- Suitable for high-speed air turbine machines (30,000-40,000 RPM), and for standard machining centers (6,000+ RPM)

Carbide Grade(s):

MTS – THREAD MILLS WITH INTERNAL COOLANT THROUGH THE FLUTES

The full-profile thread mills in this product line are capable of cutting Internal threads (only for UNJ and MJ profiles). Most of them come with internal coolant through the flutes.

Features:

- The thread depth can be up to 2.5 x Thread Diameter

- Multi (3) flutes

Carbide Grade(s):

MTS DENTAL - THREAD MILLS FOR THE DENTAL IMPLANTS INDUSTRY

A line of full-profile thread mills designed specifically for the needs of the dental implants industry. These tools feature a specially designed geometry, that includes a long overhang. This provides improved machining performance, as well as exceptional thread accuracy, while extending the life time of the tool.

Features:

- Supports threads as small as ISO M1.2 x 0.25, and 0-80 UNF

- Multi (3) flutes

Carbide Grade(s):

MTSB - THREAD MILLS WITH INTERNAL COOLANT BORE

The full-profile thread mills in this product line improve on the basic MTS thread mills, by adding a coolant bore, and either 1 or 2 coolant holes. By providing a high-pressure stream of coolant fluid through the bore, we can wash the chips away from the thread during the cutting cycle – improving tool performance, and providing superior thread accuracy. An additional benefit is the efficient cooling of the tool’s cutting edge.

Features:

- Supports threads as small as ISO M1.2 x 0.25, and 0-80 UNF

- The thread depth can be up to 4 x Thread Diameter (for some tools)

- Multi (3-4) flutes

- Suitable for high-speed air turbine machines (30,000-40,000 RPM), and for standard machining centers (6,000+ RPM)

Recommended Usage:

- Thread milling operations in horizontal machining centers, especially cases where the chips are concentrated at the buttom of the thread, and external coolant can’t wash them away.

- Complicated applications, when the external coolant is inefficient, or can’t reach the machined area

- Cases where the tool collet is too close to the application pre-hole, which causes it to block the external coolant

Carbide Grade(s):

MTI – THREAD MILLS FOR DEEP PARTS (PARTIAL PROFILE)

A product line of partial-profile thread mills, optimized for threading deep parts. The tools of this line are compatible with a wide range pitches and profiles, and support both Internal and External threads.

Features:

- Supports threads as small as ISO M1.6 x 0.25, and 0-80 UNF

- Both 60° and 55° profiles supported

- Multi (3) flutes

Carbide Grade(s):

MTI – THREAD MILLS FOR DEEP PARTS (PARTIAL PROFILE, THROUGH COOLANT)

This product line offers partial-profile thread mills that improve on the basic MTI partial-profile range, by adding an internal coolant (through the flutes). This prevents chip buildup, which improves the performance, and extends the lifespan of the tool. The tools of this product line support both Internal and External threads.

Features:

- Supports pitches as small as 0.5 mm (Internal) / 0.4 mm (External)

- Capable of cutting threads up to 50 mm deep

- Only 60° profiles are supported

- Multi (4-5) flutes

Carbide Grade(s):

MTI – THREAD MILLS FOR DEEP PARTS (FULL PROFILE)

A product line of full-profile thread mills that can be used to cut Internal threads.

Features:

- Supports threads as small as ISO M1 x 0.25, and 0-80 UNF

- Depending on the profile, the thread depth can be up to 3.5 x Thread Diameter

- Multi (3-4) flutes

Carbide Grade(s):

FMTI – THREAD MILLS WITH ADDITIONAL FLUTES

The full profile thread mills of this product line feature a large number of flutes (up to 7). This allows the tools to achieve significantly shorter machining times, as well as increase the productivity in general. Only internal threads are supported.

Features:

- The smallest supported threads are ISO M1.6 x 0.35, and 1-72 UNF

- The thread depth can be up to 2 x Thread Diameter

- Multi (5-7) flutes

Carbide Grade(s):