Family Overview

A family of high-performance end mills, created for applications where high material removal rates are required, like slotting, shouldering, and helical plunging. Compatible with a wide range of materials.

Features:

- High Performance Cutting (HPC): High feed rates supported

- Center cutting

- Innovative tool geometry enables low vibration machining

This range of solid carbide end mills consists of the following lines:

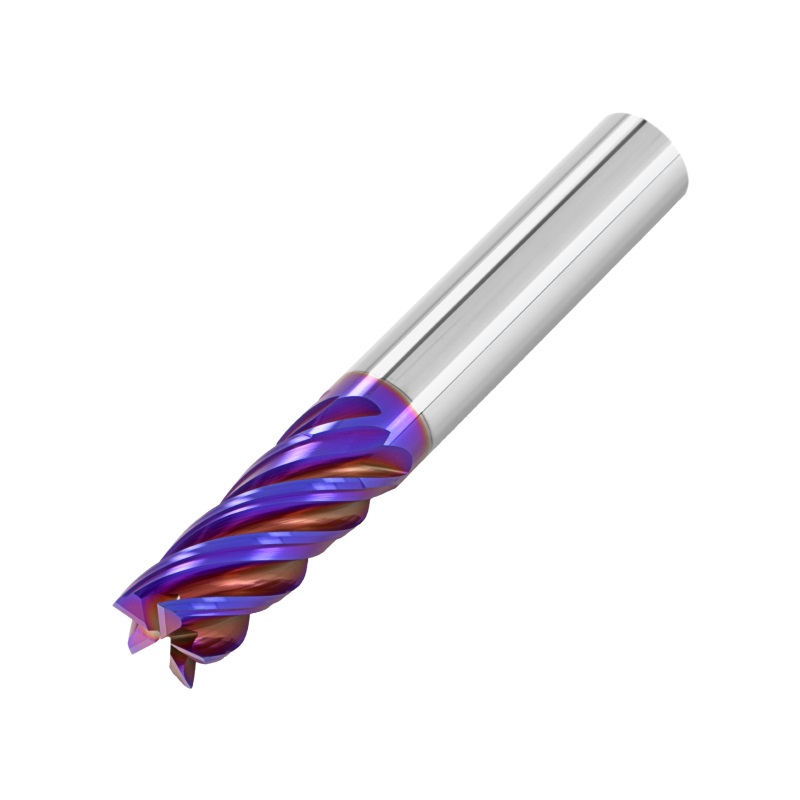

SOLID CARBIDE END MILLS

These solid carbide end mills are availble in several designs: Short (4 flutes), Long (4-5 flutes), and Extra-Long (6 flutes).

Features:

- One tool can be used for both semi-finishing, and fine-finishing operations

Carbide Grade(s):

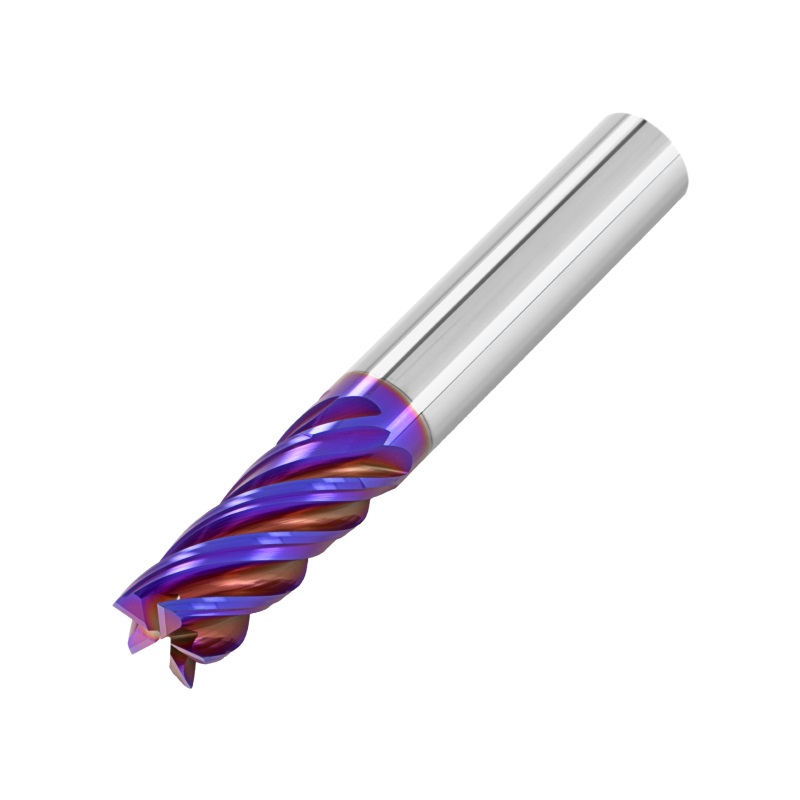

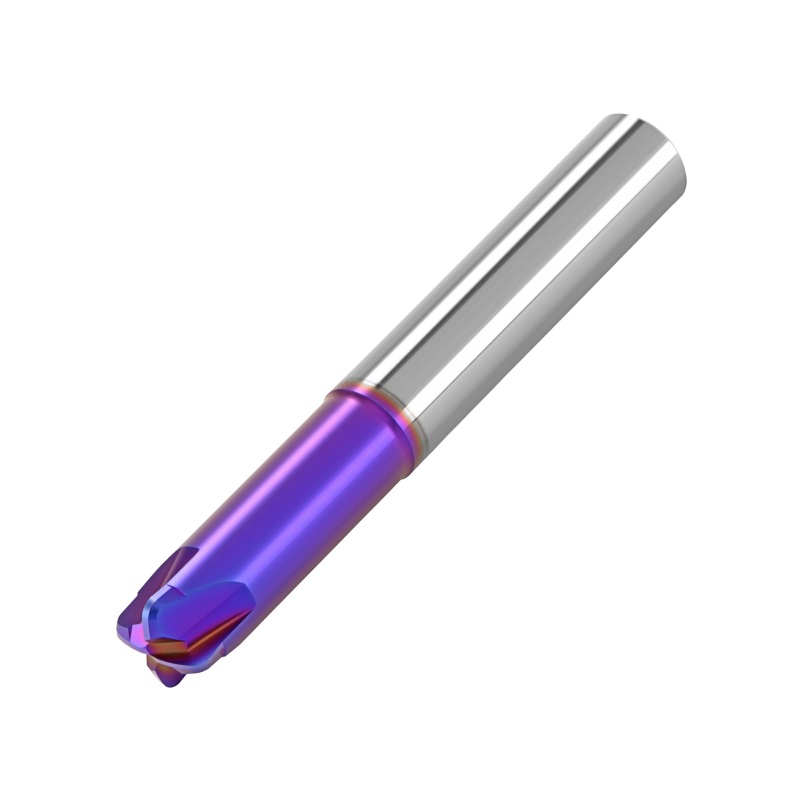

SOLID CARBIDE END MILLS WITH CORNER RADIUS

A variation on the end mills from the basic product line, these tools are also available in several different designs, and feature 4-7 flutes per tool. These end mills come with rounded edges (unlike the sharp edges in the previous line).

Features:

- The tools can be used for both semi-finishing, and fine-finishing operations

Carbide Grade(s):

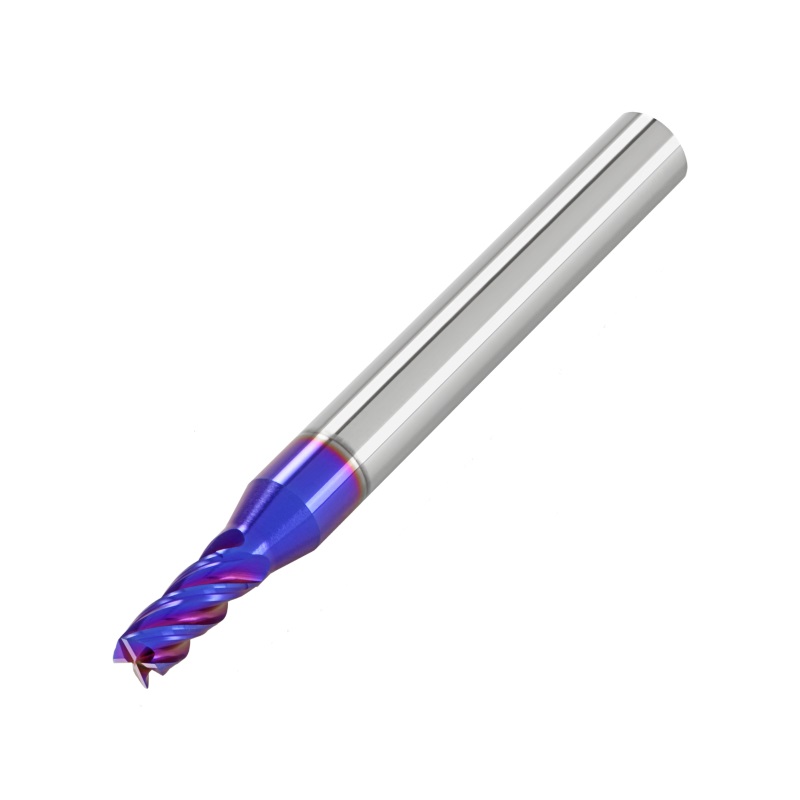

SOLID CARBIDE END MILLS WITH CORNER RADIUS AND NECK

Another version with a slightly different geometry. These solid carbide end mills feature 4-6 flutes per tool, and also come with rounded edges.

Features:

- The tools can also be used for both semi-finishing, and fine-finishing operations

Carbide Grade(s):

BALLNOSE END MILLS

Ballnose-shaped end mills. These solid carbide tools feature 4 flutes, and are available in two designs: With or Without a neck.

Carbide Grade(s):

SOLID CARBIDE END MILLS FOR ALUMINUM MACHINING

A product line of solid carbide end mills, optimized for working with aluminum.

Features:

- Multi (3) flutes

- Smooth-polished flutes

- Open flute design for improved chip removal from the cutting area

Carbide Grade(s):

SOLID CARBIDE END MILLS FOR ALUMINUM (W. CORNER RADIUS)

The solid carbide end mills in this product line have been engineered for machining aluminum. These tools have rounded edges (as opposed to the sharp edges of the tools in the basic product line).

Features:

- Multi (3) flutes

- Smooth-polished flutes

- Open flute design for improved chip removal from the cutting area

Carbide Grade(s):

HIGH FEED END MILLS

A line of end mills designed for high feed rates with shallow cutting depths. The optimized cutting edge geometry of these tools enables cycle times to be reduced, thus improving productivity.

These tools should be on the top of your list when dealing with applications with deep and shallow workpiece features, 3D profiling, mold & die applications, or machining in unstable conditions.

Features:

- Long neck length (up to 3xD), allowing the use of techniques such as ramping and helical interpolation

- Same tool can be used for roughing and semi-finishing operations

- Short flutes and large core for high rigidity

- Compatible with materials up to 62 HRc

Carbide Grade(s):