Family Overview

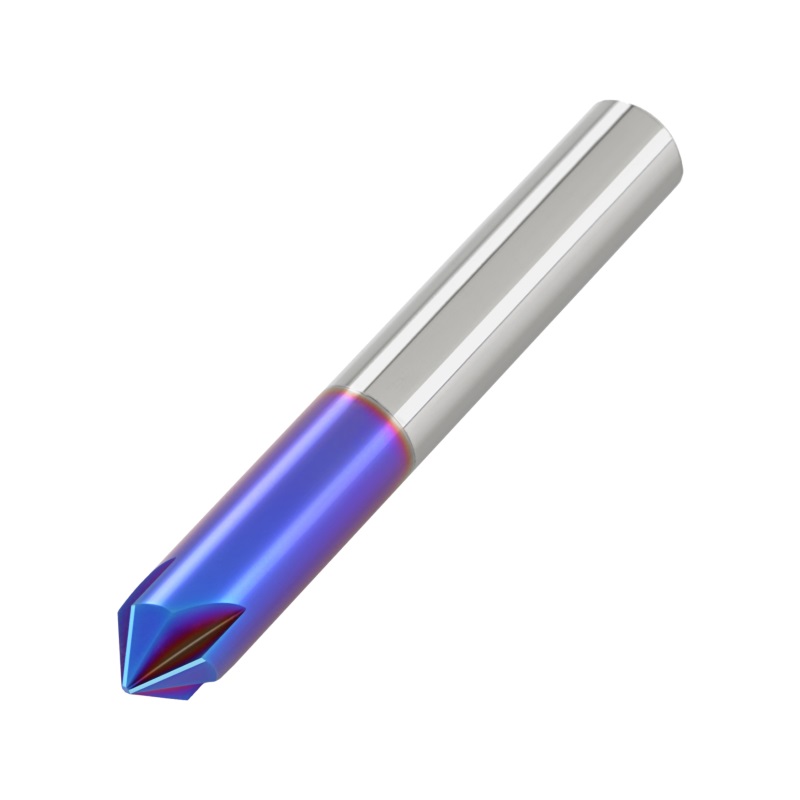

Tools from the Mini Chamfer family provide an optimal solution for back chamfering, deburring, and grooving. Their performance is aided by the multi-layer PVD coating (MT8). As such they are resistant to extremely high heat, while remaining compatible with a wide range of materials.

Features:

- Variety of profile angles available: 45° / 60° / 90° / 150°

- Spiral flutes enable smooth cutting action

This family of products consists of the following lines:

STANDARD TOOLS

Our basic line of solid chamfering tools.

Features:

- 90° or 60° profile angles

- Various shank diameters supported (3 – 12 mm)

- 3 – 6 flutes

- Double side cutting

Carbide Grade(s):

DOVETAIL 45° TOOLS

A line of solid tools designed for cutting dovetail grooves.

Features:

- 45° profile angle

- 3 flutes

- Supports only single-side cutting

Carbide Grade(s):

150° TOOLS

Features:

- 150° profile angle

- 3 flutes

- Double side cutting

Carbide Grade(s):

RADIUS FILLET END-MILLS

A line of solid carbide end-mills for radius filleting applications.

Features:

- Multi (2-4) flutes

- A cylindrical shank (using the DIN 6535-HA form)

Carbide Grade(s):

COUNTERSINK END-MILLS

A line of solid carbide end-mills designed for 45°/30° chamfering and deburring applications.

Features:

- 4 flutes

- A cylindrical shank (using the DIN 6535-HA form); Weldon shank available upon request

Carbide Grade(s):